Input parameters: Three phase,AC380V±10% ,50HZ

Output parameters: DC 0~40V 0~1000A

Output mode: Common DC output

Cooling method: Air cooling

Power supply type: IGBT-based power supply

Application Industry: Anodizing, Oxidation of aluminium profile

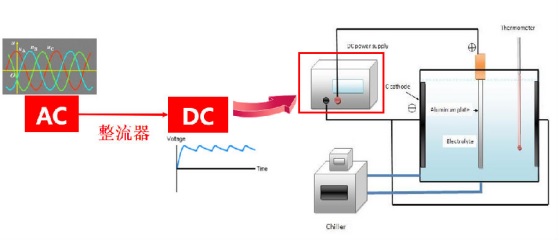

Anodizing is a kind of electrochemical oxidation process, which is mainly used for the surface treatment of aluminum and its alloys. Through anodic oxidation, a thick and hard aluminum oxide film can be formed on the surface of aluminum, which not only has good corrosion resistance, but also improves the abrasion resistance and adhesion of aluminum, and also improves the appearance through coloring treatment. Anodic oxidation is achieved through an electrolysis reaction, in the electrolysis tank, aluminum parts as the anode, usually using lead, aluminum or stainless steel as the cathode. The electrolyte is usually sulfuric acid, oxalic acid or other acidic solutions. Under the action of an electric current, an oxidation reaction occurs on the surface of aluminum, producing aluminum oxide (Al₂O₃). As the current continues, the oxide film gradually thickens. The thickness of the anodized film usually ranges from a few microns to several hundred microns. The thickness and characteristics of the film can be controlled by adjusting parameters such as current density, electrolyte composition and temperature. Rectifiers convert alternating current (AC) to direct current (DC) to provide a steady current for the electrolysis process. The rectifier power supply allows precise control of the current magnitude and waveform, which affects the thickness and quality of the oxide film. By adjusting the current density, different oxidizing effects can be achieved. During the anodizing process, the resistance of the electrolyte will change with the formation of the oxide film, and the rectifier power supply can automatically adjust the output voltage to maintain the stability of the current. Rectifier power supplies are usually equipped with over-current, over-voltage and short-circuit protection functions to ensure the safety of the electrolysis process and the reliability of the equipment. The digital control function, which can be connected with computer system, realizes automatic monitoring and data recording to improve production efficiency and product consistency. Anodizing is an important surface treatment technology. Through reasonable power supply control, the quality and performance of the oxide film can be optimized to meet different application requirements.

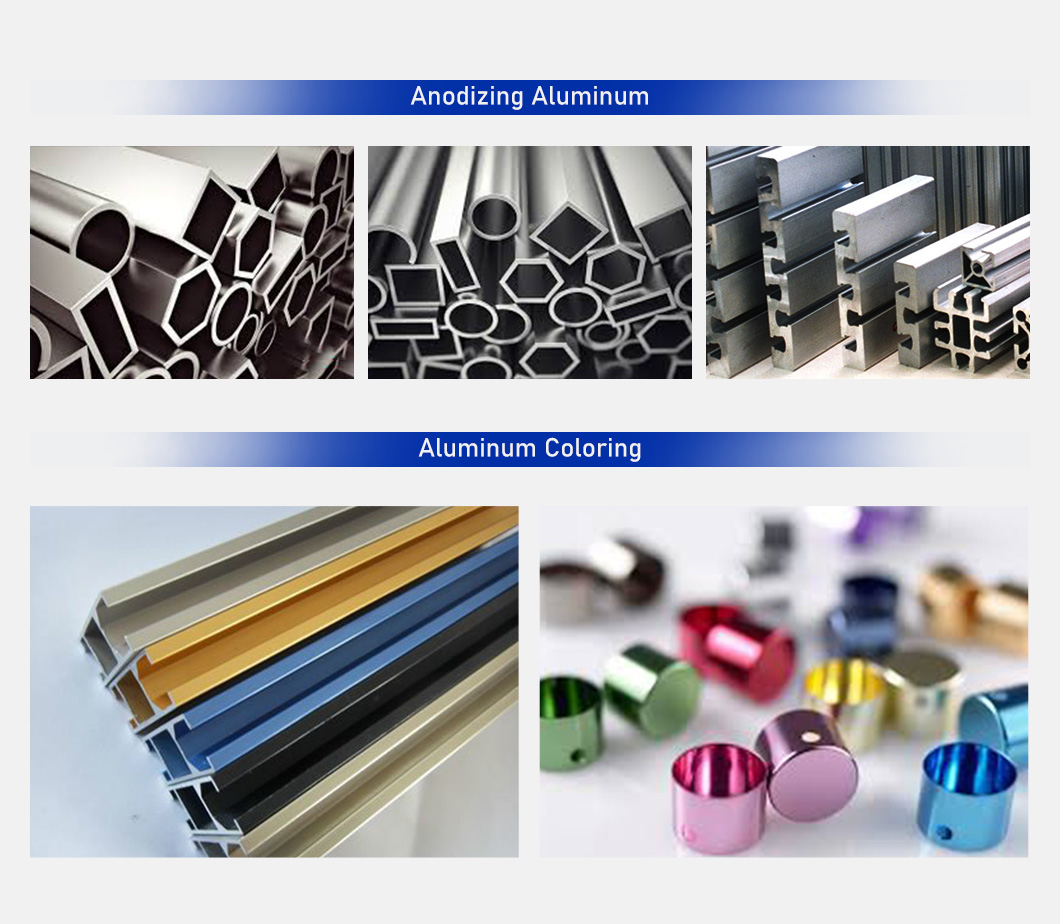

Anodize oxidation includes both aluminum anodizing and hard anodizing. Anodize oxidation (anodize oxidation), electrochemical oxidation of metals or alloys. The process of forming a layer of oxide film on aluminum products (anodes) under the action of an applied current in aluminum and its alloys under the corresponding electrolyte and specific process conditions. The so-called anodize oxidation of aluminum is an electrolytic oxidation process in which the surface of aluminum and aluminum alloys is usually transformed into a layer of oxide film, which has protective, decorative and some other functional properties.

Aluminum oxidation coloring, using artificial methods to make aluminum and its alloy products surface to generate a layer of oxide film (Al2O3) and apply different colors, in order to improve the wear resistance of aluminum, prolong the service life and increase the color and beauty. The basic process of oxidation coloring is aluminum surface treatment, oxidation, coloring and subsequent hydration sealing, organic coating and other treatment processes. The coloring methods of oxide film are chemical coloring, electrolytic coloring and natural coloring, etc.

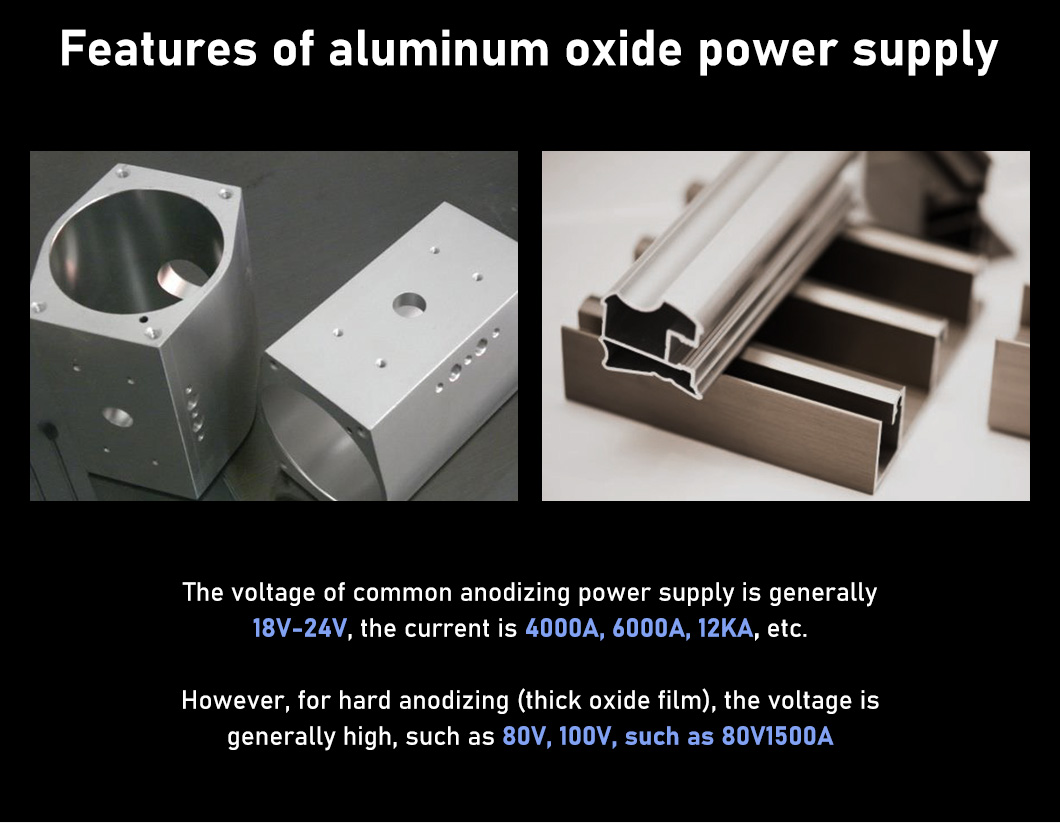

General decorative anodize oxidation requires dc power supply voltage is usually 20V-24V, hard anodize oxidation according to the process, the voltage is usually higher, sometimes up to 80V, 100V, 120V, etc., the current depends on the size of the anodized workpiece, from several hundred to tens of thousands of amperes. At present, the use of high frequency switching power supply as anodize oxidation rectifier has become a general trend, its advantages are shorter oxidation time, more energy saving, less space, lighter weight and more convenient maintenance.

Characteristic Types |

Parameter Items |

Technical Requirements |

| Power Types | Power types | High-frequency Power Supply |

| Model and specifications |

TDFB-1000A/40V

|

|

| Cooling mode | Air-cooled | |

| Switch tube type | IGBT | |

| Input Characteristics | Rated Input Voltage | Three-phase, AC380V±10% ,50~60HZ |

| Rated Input Power | 45.8KVA | |

| Rated Input Current | AC 70A | |

| Input Power Factor | COSΦ≥0.95 | |

| Output Characteristics | Output Voltage | DC 0~40V |

| Output Current | DC 0~1000A | |

| According to accuracy | 1A,0.1V | |

| Rated Output efficiency | ≥90% | |

| Environmental Conditions | Installation site | Indoor installations |

| Altitude | ≤2000 meters | |

| Ambient temperature | -20℃~45℃ | |

| Relative humidity | ≤91% | |

| Control Mode | Operating mode | PLC, ADDA, Ethernet, RS485 and RS232 |

| External Dimension | Height*Width*Depth | H275mm×W692mm×D935mm |

| Protection Characteristics | With over voltage, over current, overload, short circuit, overheating and other abnormal self-protection function | |

| Application | Model | Output Parameters |

| Aluminum anodizing | TBSB-2500A25V | 25Vdc/2500A |

| TBSB-100A30V | 30Vdc/100A | |

| TBSB-1000A25V | 25Vdc/1000A | |

| TBSB-750A25V | 25Vdc/750A | |

| TBSB-700A40V | 40Vdc/700A | |

| TBSB-500A40V | 40Vdc/500A | |

| TBSB-300A50V | 50Vdc/300A | |

| TBSB-200A24V | 24Vdc/200A | |

| TBSB-100A40V | 40Vdc/100A | |

| TBSB-100A24V | 24Vdc/100A | |

| TBSB-50A20V | 20Vdc/50A | |

| TBSB-16KA22V | 22Vdc/16KA | |

| TBSB-14KA22V | 22Vdc/14KA | |

| TBSB-12KA22V | 22Vdc/12KA | |

| TBSB-16KA22V | 22Vdc/16KA | |

| TBSB-12KA22V | 22Vdc/12KA | |

| TBSB-1000A15V | 15Vdc/1000A | |

| TBSB-18KA25V | 25Vdc/18KA | |

| TBSB-12KA20V | 20Vdc/12KA | |

| TBSB-20KA150V | 150Vdc/20KA | |

| KGFB-2000A20V | 20Vdc/2000A | |

| KGSB-50KA1000V | 1000Vdc/50KA | |

| TBSB-22KA22V | 22Vdc/22KA | |

| KGFB-1500A/80V | 80Vdc/1500A | |

| TBSB-15KA/22V | 22Vdc/15KA | |

| KGSB-4KA250V | 250Vdc/4KA | |

| TBSB-24KA/22V | 22Vdc/24KA | |

| Colouring | DC/AC-500A/30V | DC/AC-500A/30Vdc |

| DC/AC-12KA25V | DC/AC-12KA25Vdc |

Hot Tags:1000A 40V Aluminium Anodizing Rectifier for Electroplating,Aluminum Anodizing Rectifier,igbt electroplating rectifier,aluminum electrolysis rectifier,Aluminum oxidation coloring,plating rectifier manufacturers,electroplating rectifiers for sale,plating rectifier for sale China,USA,Germany,Sweden,factory,price

Liyuan Haina Rectifier, the professional manufacturer in IGBT and SCR rectifier, committed to providing you with quality solutions and products.

Get more details? We’ll response as soon as possible (within 12 hours).

Liyuan Haina Rectifier, the professional manufacturer in IGBT and SCR rectifier, committed to providing you with quality solutions and products.

Get more details? We’ll response as soon as possible (within 12 hours).