Input parameters: AC6KV, AC10KV, AC 35KV etc, 50~60HZ

Output parameters: DC 0~10KV 0~50KA

Output mode: Common DC output

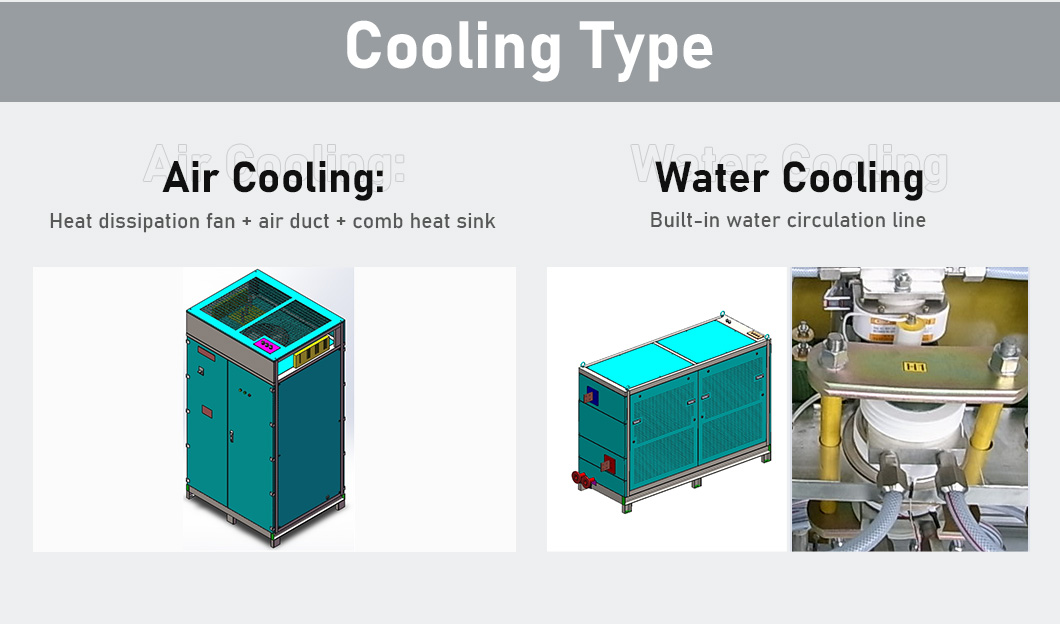

Cooling method: Water cooling

Power supply type: Silicon controlled rectifier

Application Industry: Salt water, potassium salt electrolytic caustic soda, potassium alkali, sodium, potassium chloride electrolytic potassium chlorate, potassium permanganate.

Sodium hydroxide, chemical formula NaOH, commonly known as caustic soda, caustic soda, caustic soda, is a strong corrosive alkali, generally in the form of flakes or granules, easily soluble in water (exothermic when dissolved in water) and alkaline solution, and deliquescent, easily absorbing water vapor in the air (deliquescence) and carbon dioxide (deterioration).

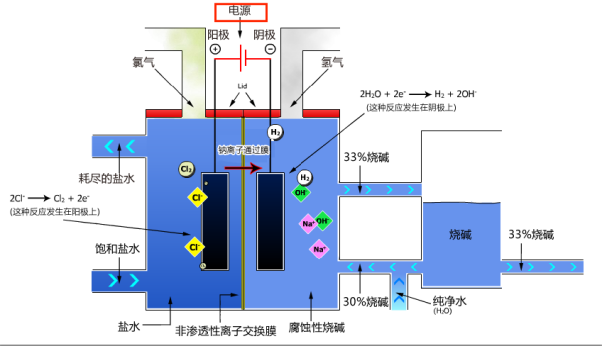

The widely used caustic soda production is mainly ion membrane electrolysis, the raw material is crude salt NaCl, electrolysis is an important part of the caustic soda production process, but also the highest electricity consumption of the process, and electrolysis must provide a reliable and stable direct current, direct current needs to be converted through the grid of alternating current, this process becomes rectification, the equipment to provide direct current is called rectifier. The ion film caustic soda rectifier cabinet adopts the semi-controlled device silicon controlled as the core, through the silicon controlled phase shift control technology, to realize the variable current and provide stable and reliable DC power for ion film caustic soda electrolysis, which is the core component of ion film caustic soda.

| Input voltage | AC6KV, AC 10KV, AC 35kv, etc., 50-60HZ |

| Voltage regulation precision | ≤1% |

| Current regulation precision | ≤1% |

| Rated efficiency | ≥90% |

| Operation environment | -10-40℃ |

| Storage temperature | -20-50℃ |

| Inversion frequency | 18KHZ |

| Cooled mode | Water cooled and oil immersed water cooled |

| Trigger system | Full digital trigger regulation system |

| Operation conditions | 24-hour operation under full load(under 1500m) |

| Output voltage range | 0-1000V |

| Output current range | 0-500000A |

|

※Ok to customize as requirements※ |

|

| Application | Model | Output Parameters |

| Electroplating, Electrolysis, Electrochemistry, Anodizing, Electrophoresis, Smelting, Electrocasting, Communication and other fields. | KES-11KA/220V | 220Vdc/11KA |

| KES-13.5KA/90V | 90Vdc/13.5KA | |

| KES-26KA/123V | 123Vdc/26KA | |

| KES-33KA/135V | 135Vdc/33KA | |

| KES-41KA/115V | 115Vdc/41KA | |

| KES-41KA/300V | 300Vdc/41KA | |

| KES-43KA/249V | 249Vdc/43KA | |

| Aluminum, magnesium, lead, zinc, copper, manganese, bismuth, nickel and other non-ferrous metal electrolysis; | KES-45KA/210V | 210Vdc/45KA |

| KES-40KA/70V | 70Vdc/40KA | |

| KES-50KA/45V | 45Vdc/50KA | |

| KES-33KA/245V | 245Vdc/33KA | |

| KES-42KA/120V | 120Vdc/42KA | |

| Salt water, potassium salt electrolytic caustic soda, potassium alkali, sodium; |

KES-35KA/110V | 110Vdc/35KA |

| KES-43KA/160V | 160Vdc/43KA | |

| KES-13.5KA/135V | 135Vdc/13.5KA | |

| KES-30KA/150V | 150Vdc/30KA | |

| Potassium chloride electrolysis to produce potassium chlorate, potassium perchlorate; | KES-15KA/120V | 120Vdc/15KA |

| KES-40KA/45V | 45Vdc/40KA | |

| KES-7000A/150V | 150Vdc/7000A | |

| KES-48KA/300V | 300Vdc/48KA | |

| KES-10KA/100V | 100Vdc/10KA | |

| Wire heating, silicon carbide heating, carbon tube furnace, graphitization furnace, melting furnace and other heating, electrolytic water hydrogen production and other large current fields. | KES-30KA/40V | 40Vdc/30KA |

| KGFB-400A/750V | 750Vdc/400A | |

| KGFB-350A/850V | 850Vdc/350A | |

| KGFA-3000A/26V | ±26Vdc/3000A | |

| KGFB-400A/380V | 380Vdc/400A | |

| KES-8.7KA/855V | 855Vdc/8.7KA | |

| KHS-7KA/150V | 150Vdc/7KA |

Hot Tags:10KV 50KA Rectifier For Caustic Soda Process,Caustic Soda Rectifier,dc power supply for electrolysis,igbt electroplating rectifier,Silicon controlled rectifier,China,manufacturers,factory

Liyuan Haina Rectifier, the professional manufacturer in IGBT and SCR rectifier, committed to providing you with quality solutions and products.

Get more details? We’ll response as soon as possible (within 12 hours).

Liyuan Haina Rectifier, the professional manufacturer in IGBT and SCR rectifier, committed to providing you with quality solutions and products.

Get more details? We’ll response as soon as possible (within 12 hours).