- Home

- Products

- Application

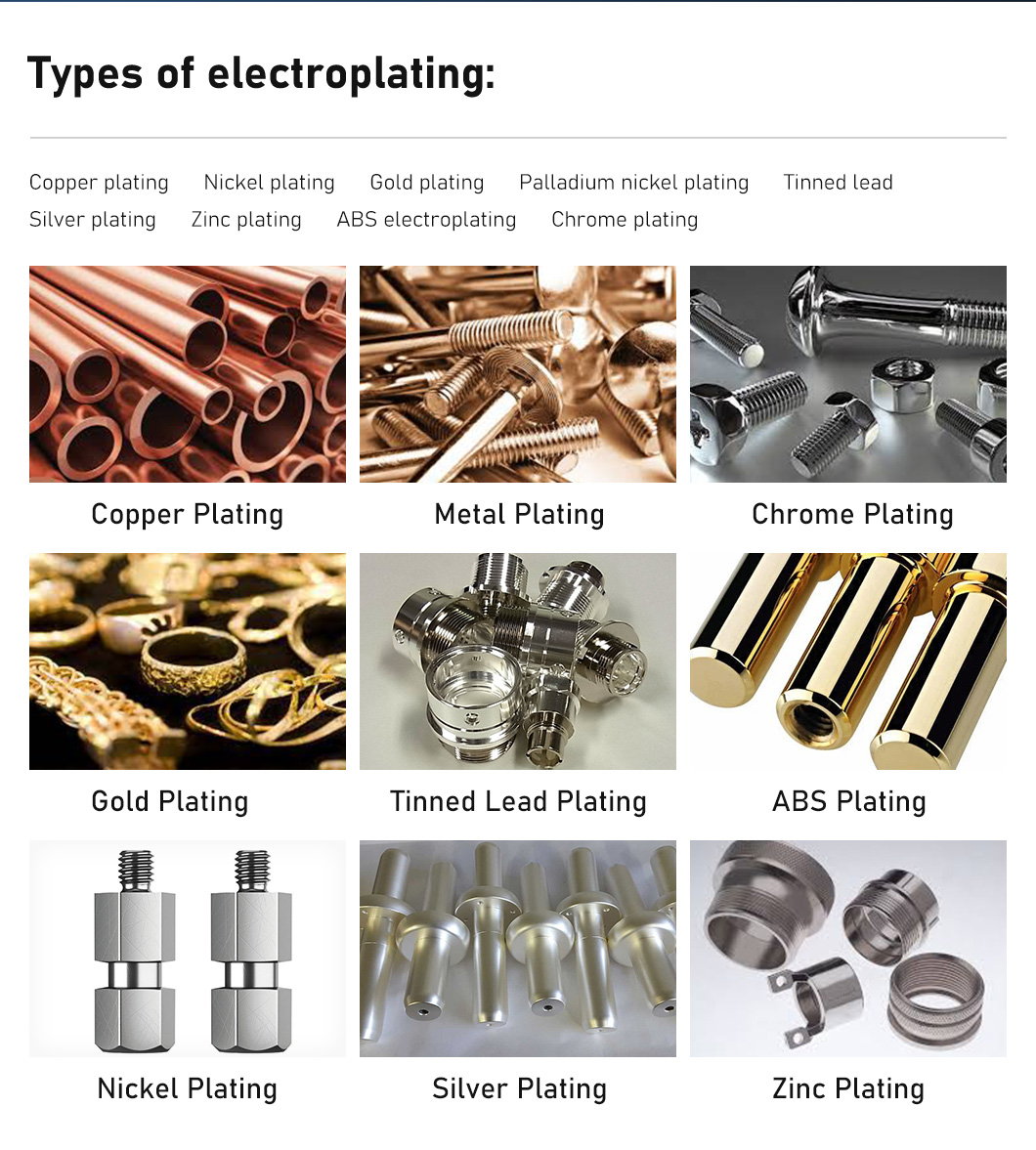

- Surface Treatment Industry

- Nickel Plating Industry

- Water Treatment Industry

- Hydrogen electrolysis industry

- Anodizing Aluminum industry

- Copper Electroplating Industry

- Copper Electrolysis Industry

- Rare Earth Smelting Industry

- Wastewater Treatment Industry

- Metallurgy Industry

- Hard Chrome Plating industry

- Hardware Plating Industry

- Electrophoretic Industry

- About Us

- Services

- News

- Contact Us