Input parameters: Three phase, AC380V±10% ,50HZ

Output parameters: DC 0~30V 0~800A

Output mode: Common DC output

Cooling method: Water cooling

Power supply type: IGBT-based

Application Industry: Surface treatment industry, such as hard chrome, zinc and nickel plating

Copper plating is a common surface treatment process used to improve the conductivity, corrosion resistance and aesthetics of metal surfaces. Copper plating is the process of coating a metallic or non-metallic surface with a layer of copper by electroplating or chemical plating. This process creates a uniform layer of copper, usually between a few microns and several hundred microns thick. There are two types of copper plating: electroplating and chemical plating. Electroplating uses an electric current to reduce copper ions from an electrolyte to the surface of the substrate, forming a copper layer. The electroplating process requires the use of a power source, a copper salt solution, and an appropriate electrolyte. Chemical plating does not rely on an electric current, but instead deposits copper on the surface of the substrate through a chemical reaction. This method allows copper plating on non-conductive materials.

Copper plating is widely used in the manufacture of circuit boards to improve electrical conductivity and solderability, on some mechanical parts to improve wear and corrosion resistance, and for decorative purposes, such as on artwork and home furnishings to add to their aesthetic appeal. Copper plating improves electrical conductivity, protects the substrate from oxidation and corrosion, and prolongs service life. There is usually good adhesion between the copper layer and the substrate to ensure the stability of the plating. During the copper plating process, parameters such as current density, temperature and pH need to be controlled to ensure the quality of the coating. After copper plating, post-treatment, such as nickel plating or coating with a protective layer, is often required to improve corrosion resistance and prevent oxidation. The copper plating process can effectively enhance the performance and appearance of the material.

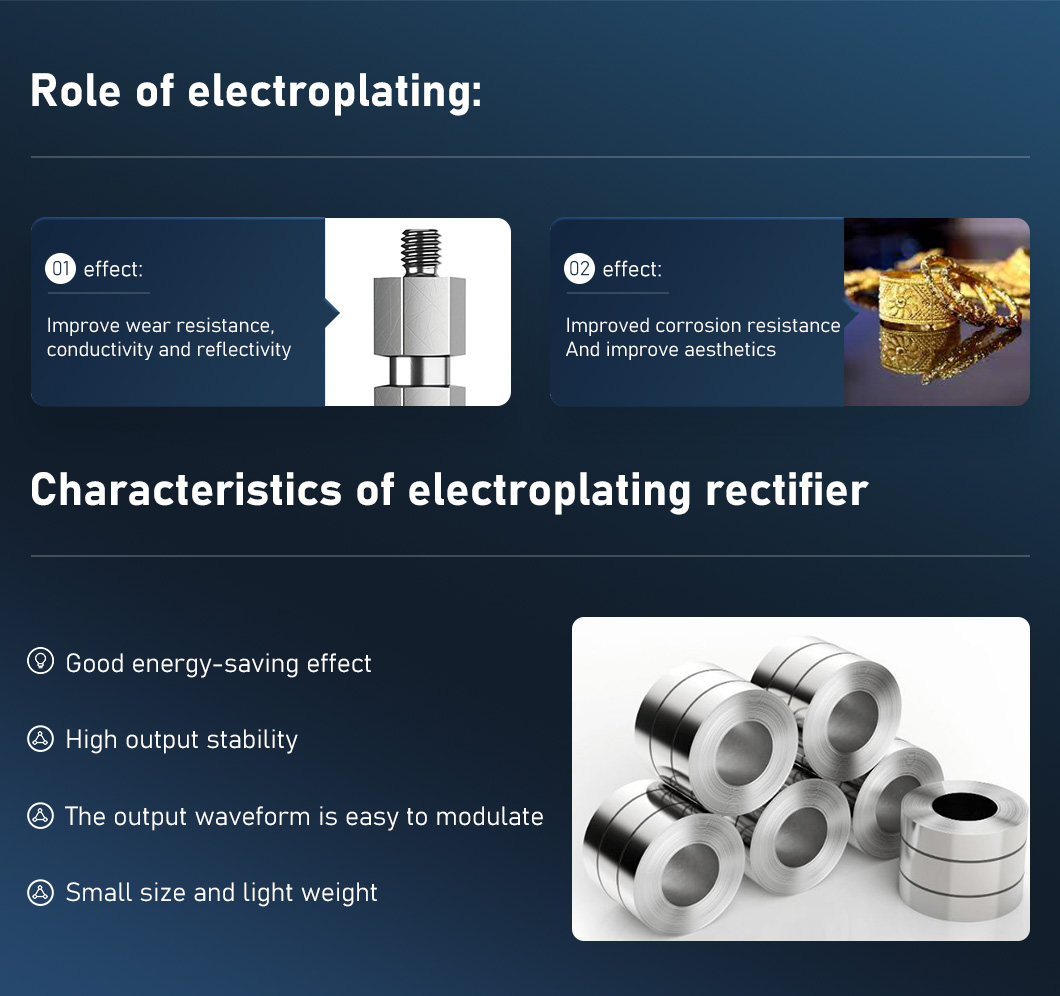

Electroplating is the process of applying a thin layer of other metals or alloys on the surface of certain metals by electrolysis. It is a process of applying a metal film to the surface of metals or other materials to prevent metal oxidation (such as rust), improve wear resistance, electrical conductivity, reflectivity, corrosion resistance (copper sulfate, etc.) and enhance aesthetics.

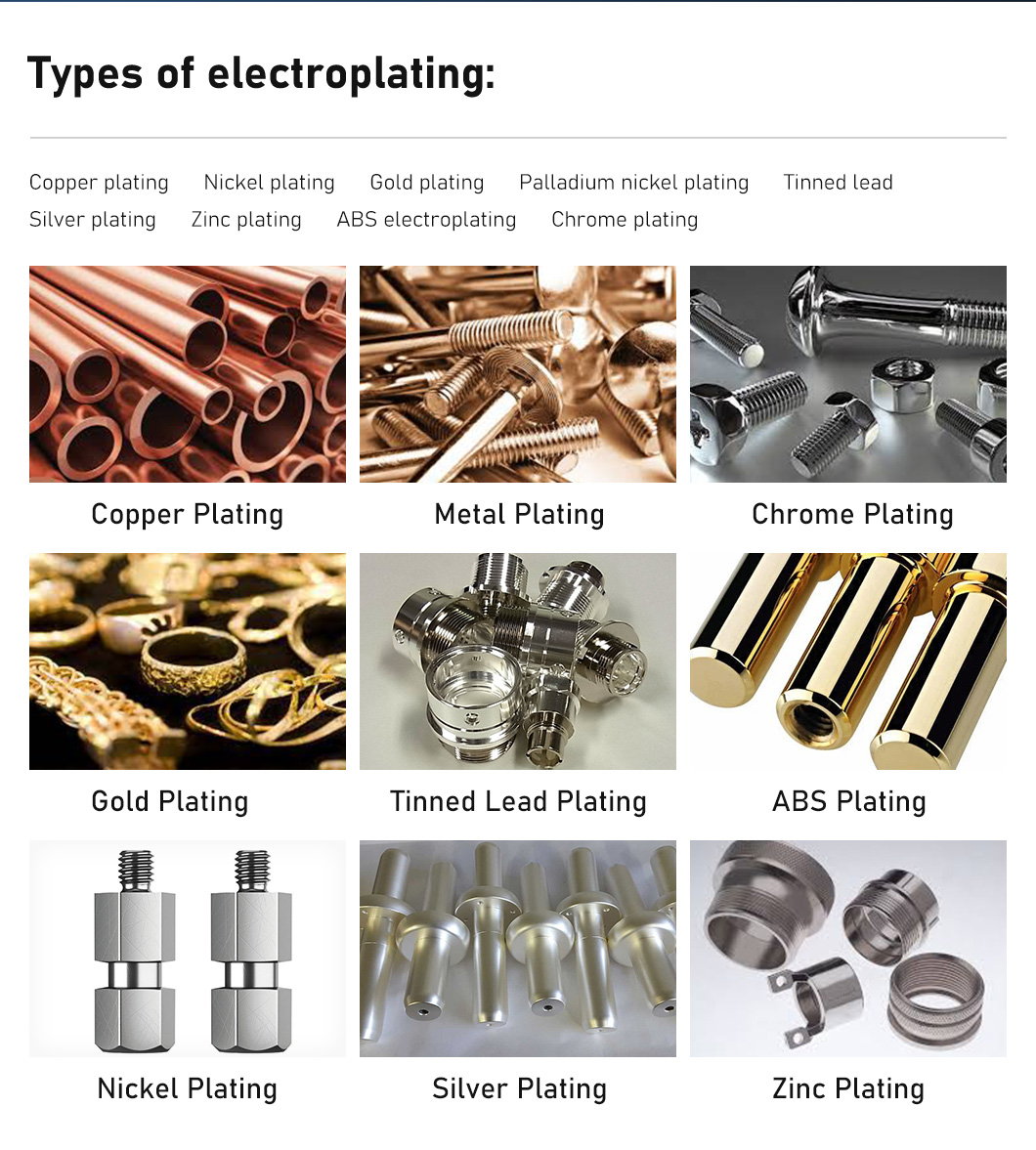

Types of plating

Elements of electroplating

| Items | Parameter Items | Parameter details |

| Input | Rated voltage | Three phase AC380V±10% 50HZ |

| Power factor | PF≥0.95 | |

| Output | Rated Voltage | DC 0~30V Constant adjustable |

| Rated Current | DC 0~800A Constant Adjustable | |

| Current precision | ≤1% | |

| Voltage precision | ≤1% | |

| Rated Efficiency | ≥90% | |

| Insulation | Insulation resistance | Input—Output:≥5MΩ |

| Input—Case: ≥5MΩ | ||

| Output—Case: ≥5MΩ | ||

| Protection | Self-protective function under the abnormal situations such as over-voltage, over-current, default phase,short circuit, overheating and so on | |

| Other Characters | Cooling type | Water cooling |

| Operation | Products can be continuously full-load running | |

| Load Grade | Class Ⅱ | |

| Insulation Grade | Class B | |

| Application | Model | Output Parameters |

| Plating | TBFB-500A/5V | 5Vdc/500A |

| TBFB-600A/10V | 10Vdc/600A | |

| TBFB-1000A/10V | 10Vdc/1000A | |

| TBFB-1500A/10V | 10Vdc/1500A | |

| TBFB-5000A/15V | 15Vdc/5000A | |

| HISB-200A12V | 12Vdc/200A | |

| HISB-300A12V | 12Vdc/300A | |

| HISB-500A12V | 12Vdc/500A | |

| HISB-1000A8V | 8Vdc/1000A | |

| HISB-1000A12V | 12Vdc/1000A | |

| HISB-1500A12V | 12Vdc/1500A | |

| HISB-2500A12V | 12Vdc/2500A | |

| HISB-3000A12V | 12Vdc/3000A | |

| HISB-4000A12V | 12Vdc/4000A | |

| HISB-5000A12V | 12Vdc/5000A | |

| HISB-7000A12V | 12Vdc/7000A | |

| TBSB-8000A/12V | 12Vdc/8000A | |

| TBSB-4000A/12V | 12Vdc/4000A | |

| TBSB-8000A/12V | 12Vdc/8000A | |

| TBSB-3000A/12V | 12Vdc/3000A | |

| TBSB-400A/4V | 4Vdc/400A | |

| TBSB-800A/12V | 12Vdc/800A | |

| TBFA-4000A/12V | ±12Vdc/4000A | |

| HMFB-10A5V | 5Vdc/10A | |

| TBFA-2000A/12V | ±12Vdc/2000A | |

| TBFBZ-300A/5V | 5Vdc/300A | |

| TBFBZ-800A/5V | 5Vdc/800A | |

| TBFBZ-600A/6V | 6Vdc/600A | |

| TBSB-12KA/12V | 12Vdc/12KA | |

| TBSB-6000A/12V | 12Vdc/6000A | |

| TDSB-10KA100V | 100Vdc/10KA |

Hot Tags:30V 800A Electroplating Power Supply For Surface Treatment,Electroplate Rectifier,plating rectifier,electroplating rectifier,plating rectifier manufacturers,rectifier for electroplating China,factory,sale,price

Liyuan Haina Rectifier, the professional manufacturer in IGBT and SCR rectifier, committed to providing you with quality solutions and products.

Get more details? We’ll response as soon as possible (within 12 hours).

Liyuan Haina Rectifier, the professional manufacturer in IGBT and SCR rectifier, committed to providing you with quality solutions and products.

Get more details? We’ll response as soon as possible (within 12 hours).