Input parameters: three-phase AC415V 50Hz Complies with National Power Quality Standards

Output voltage: DC 0~80V adjustment

Output current: DC 0~700A adjustment

Cooling method: Water cooling

Power supply type: IGBT-based power supply

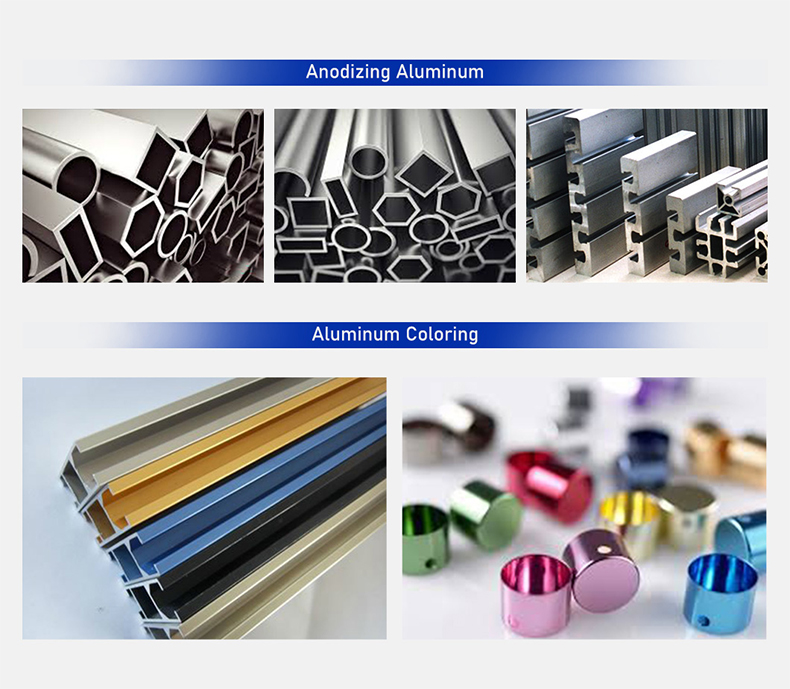

Application Industry: Surface treatment industry, such as anodizing and oxidation of aluminum profiles.

Anodizing, an essential surface treatment process, involves the electrochemical oxidation of metals or alloys to form an oxide film. This technique, particularly used for aluminum and its alloys, enhances the material’s wear resistance, durability, and aesthetic qualities. Anodizing, including both aluminum anodizing and hard anodizing, is widely employed to provide protective, decorative, and functional properties to aluminum products.

In anodizing, an applied current forms a protective oxide film (Al2O3) on the surface of aluminum. The film can be further enhanced with various coloring methods, including chemical, electrolytic, and natural coloring, to improve both the wear resistance and appearance of the metal. This process is typically followed by hydration sealing, organic coating, or other treatments to further enhance the properties of the anodized surface.

Anodizing also includes hard anodizing, which requires higher voltages (up to 120V or more) compared to decorative anodizing, where the voltage is typically between 20V-24V. The current for anodizing is adjusted based on the size of the workpiece, ranging from several hundred to tens of thousands of amperes. To achieve consistent and efficient results in anodizing, particularly for hard anodizing processes, the use of an Anodizing Rectifier has become essential.

The Anodizing Rectifier utilizes high-frequency switching technology, offering numerous advantages such as shorter oxidation times, energy savings, space efficiency, lighter weight, and easier maintenance. The Anodizing Rectifier ensures stable, high-quality results while minimizing energy consumption, making it indispensable in industries where aluminum anodizing plays a critical role.

Incorporating the Anodizing Rectifier into anodizing systems not only improves the precision of the process but also enhances overall efficiency. These rectifiers are essential in applications like aluminum oxidation coloring, where they facilitate optimal control of the oxidation process, contributing to better performance and aesthetic improvements.

Anodizing plays a crucial role in the surface treatment industry, particularly in the anodizing and oxidation of aluminum profiles. It is widely applied across various industries due to its ability to enhance the performance, durability, and aesthetic appeal of aluminum and its alloys. This electrochemical process creates a protective oxide layer on aluminum surfaces, offering benefits such as excellent corrosion resistance, high abrasion resistance, improved electrical insulation, and a long-lasting finish. Anodized aluminum products also maintain their color and appearance, even when exposed to sunlight, making them an attractive choice for both functional and decorative applications.

In industries such as aerospace, automotive, construction, and electronics, anodized aluminum is favored for its lightweight yet durable nature. Anodizing is used to improve the longevity of aluminum parts exposed to harsh environments, such as marine, automotive, and architectural applications. The process provides not only a high degree of protection against corrosion but also enhances the surface hardness, making it ideal for wear-resistant applications. In the automotive industry, anodizing is commonly used for trim parts, wheels, and chassis components, offering both aesthetic and functional benefits.

For architectural purposes, anodized aluminum profiles are extensively used in window frames, curtain walls, and structural components due to their corrosion resistance and ability to withstand environmental elements. The anodized layer also provides an excellent surface for additional coatings, including paints and dyes, allowing for a wide range of color options without compromising durability.

The anodizing process also extends to the production of electronic components and devices, where anodized aluminum is used for enclosures, heat sinks, and connectors, thanks to its non-conductive properties and ability to dissipate heat effectively.

1)Field application diagram:

2)Industry application examples:

› A very thin coating: Anodizing creates a fine, uniform oxide layer on aluminum without significantly altering the dimensions of the base material.

› Excellent corrosion protection: The anodized surface provides a highly resistant barrier against corrosion, making aluminum ideal for use in harsh environmental conditions.

› Good electrical insulator: The anodized layer acts as a dielectric, providing insulation in electronic components and electrical applications.

› Fade-resistant in sunlight: The anodized layer is highly resistant to UV degradation, ensuring long-term aesthetic appeal, even with prolonged exposure to sunlight.

› Environmentally friendly finish: Anodizing uses non-toxic, water-based electrolytes and does not involve harmful chemicals, making it an environmentally safe process.

› Inexpensive: Anodizing is a cost-effective surface treatment option that enhances the performance and longevity of aluminum without adding significant costs.

› Extremely durable, hard, abrasion-resistant, and long-lasting: The anodized layer increases aluminum’s hardness and wear resistance, extending the lifespan of the product, particularly in demanding environments.

› Features of Aluminum Oxide Power Supply: The voltage of common anodizing power supplies typically ranges from 18V to 24V, with currents of 4000A, 6000A, or 12KA. For hard anodizing, which involves creating thicker oxide films, the voltage is generally higher, such as 80V or 100V, with currents like 1500A. This high voltage ensures the formation of a more durable oxide coating, enhancing wear resistance and surface hardness.

The role of anodizing in surface treatment includes several key functions that enhance the properties and performance of aluminum and its alloys:

› Corrosion Resistance: Anodizing significantly improves the aluminum’s resistance to corrosion, making it ideal for use in harsh environments such as marine, aerospace, and automotive applications.

› Surface Hardening: The anodized layer is much harder than the underlying aluminum, providing increased wear resistance and durability. This makes anodized aluminum suitable for high-stress applications.

› Aesthetic Enhancement: Anodizing allows for a variety of coloring techniques (chemical, electrolytic, or natural coloring) that enhance the visual appeal of aluminum products, commonly used in architectural, consumer goods, and electronics industries.

› Electrical Insulation: The anodized layer acts as a dielectric, providing insulation, which is particularly useful in electrical and electronic applications like connectors, capacitors, and housings.

Improved Adhesion: The anodized surface has better adhesion properties for paints, coatings, and adhesives, making it ideal for post-treatment processes in automotive and construction industries.

› Environmentally Friendly: Anodizing is a sustainable, eco-friendly process as it does not use harmful chemicals and generates minimal waste compared to other coating methods like plating.

› Increased Wear Resistance: Anodized aluminum is highly abrasion-resistant, which makes it suitable for applications that require a durable and long-lasting finish, such as aerospace, military, and heavy-duty machinery.

› Thermal Dissipation: Anodized aluminum has better heat dissipation properties, making it ideal for applications like heat sinks and other cooling components in electronic devices.

Overall, anodizing is essential in improving the mechanical, electrical, and aesthetic properties of aluminum, providing a versatile solution for various industrial applications.

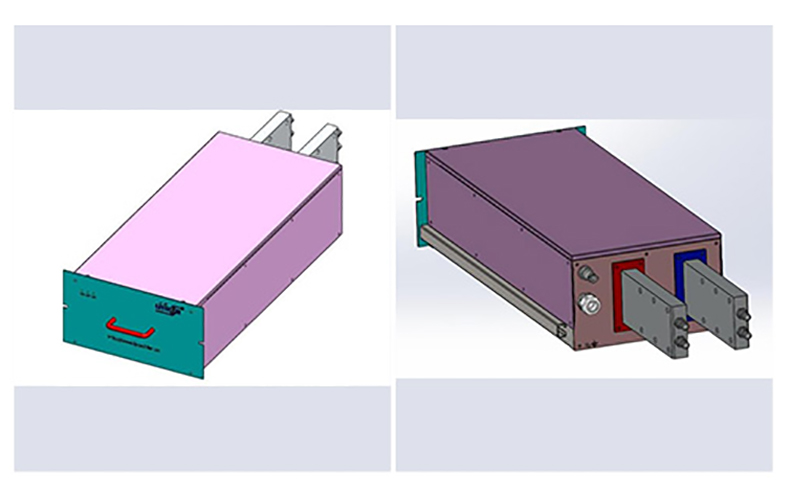

Anodizing rectifiers provide the necessary electrical current and voltage to create a protective oxide layer on aluminum. The main types include the Aluminum Anodizing Rectifier and the DC/AC Coloring Rectifier, each designed for specific anodizing requirements.

› Aluminum Anodizing Rectifier

Function: Delivers direct current (DC) to form a protective oxide layer on aluminum. Voltage typically ranges from 18V-24V for standard anodizing, and up to 80V or higher for hard anodizing.

Features:

Precise Voltage Control: Ensures optimal oxide film formation.

Stable Current: Prevents defects like uneven layers.

Energy Efficient: High-frequency switching technology reduces energy use.

Applications: Used in aerospace, automotive, and construction for corrosion-resistant aluminum products.

› DC/AC Coloring Rectifier

Function: Allows for both DC and AC currents to enable precise color effects in anodizing while maintaining the oxide layer’s integrity.

Features:

Dual Current Output: Enables fine control over color development.

Energy Efficiency: High-frequency switching reduces energy consumption.

Applications: Ideal for decorative anodized aluminum in consumer goods, architecture, and electronics.

Both rectifiers are essential for anodizing, with the Aluminum Anodizing Rectifier focusing on durability and corrosion resistance, and the DC/AC Coloring Rectifier enabling precise color control for aesthetic applications. These rectifiers ensure efficient, high-quality anodizing results tailored to industry needs.

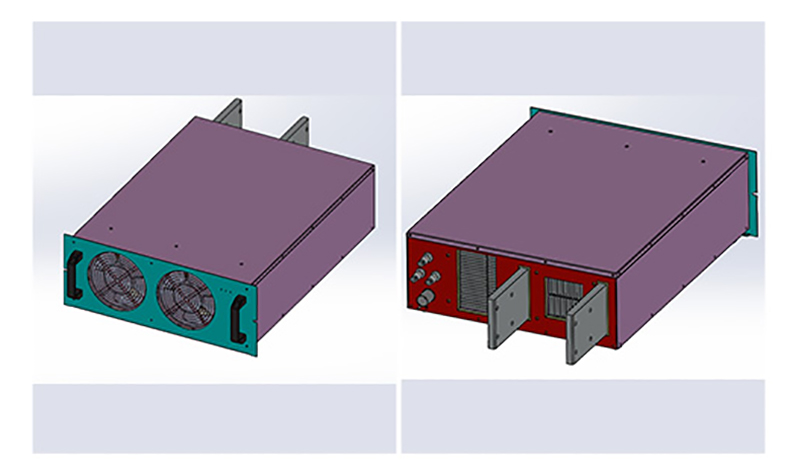

Air Cooling:Heat dissipation fan + air duct + comb heat sin

Water Cooling:Built-in water circulation line

| Type of characteristics | Parameters | Technical Requirements |

| Input characteristics | Rated input voltage | three-phase AC415V 50Hz Complies with National Power Quality Standards |

| Rated input current | AC 91.1 A | |

| Rated input power | 65.5KVA | |

| Rated input power factor | COSΦ≥0.95 | |

| Output characteristics | Output voltage | DC 0~80V adjustment |

| Output current | DC 0~700A adjustment | |

| Precision of steady current | ≤1% | |

| Precision of stable voltage | ≤1% | |

| Displayed precision | 1A, 0.1V | |

| Current ripple coefficient | ≤1%(I≥50%Id) | |

| Rated output power | ≥90%

|

|

| Insulation characteristic | Insulation resistance | Input – Output: ≥5MΩ |

| Input – Cabinet: ≥5MΩ | ||

| Output – Cabinet: ≥5MΩ | ||

| Protective characteristics | With self-protection function under non-normal cases such as over-voltage, over-current, overload, short circuit and overheating | |

| Other characteristics | Noise | ≤75dB |

| Running state | Continuous full load run of product | |

| Load level | Level II | |

| Insulation grade of the transformer | Grade B | |

| Weight | 50kg | |

» Solution

Liyuan will keep up with the world’s latest technology closely, and uphold the concept of providing customers with high-quality power supplies and professional integrated services.

With advanced design and rich experience in rectifier manufacturing, we will provide the best power solutions as well as the most stable and efficient power supply for users both at home and abroad.

» Technical Capability

LIYUAN rectifier is the most competitive brand in China

Company relies on strong technology research and development cooperation basis, created a number of advanced technology, in recent 3 years amounted to more than 30 to apply for a patent, which has nearly 10 patents of invention.

Equipped with the national electric power transformation and control engineering technology research center (branch), and has set up a loan enterprise academician workstation.

Strict implementation of ISO quality management system, and through the CE safety certification, has been implementing ERP management for many years, to achieve the network, systematic computer control, the formation of a standard, efficient modern management system.

» Qualification certification

Liyuan adhere to innovation and the continuous improvement of power conversion efficiency and product quality.

The increasing R&D investment every year, and cooperation with China’s well-known universities, we has established the research center of national electric power conversion and control engineering technology.

Especially the related core patents of high-power synchronous rectifier power supply, stay ahead of the whole industry in China.

The ISO 9001 quality management system has been fully implemented in Liyuan, including quality inspection of components in warehouse, production process inspection, and final product inspection.

We adopt advanced scientific quality management system and the most stringent testing methods in the whole process to ensure the stability and reliability of products.

» Service

› Packing

1)Small size rectifier packing in carton box separately.

2)Large size rectifier will be packed in wooden case.

3)We guarantee that all the packing is intact when it reaches its destination.

› Shipping

1)30-45 Days after payment.

2)Transport: DHL, FEDEX, UPS, Air shipping, Boat shipping

3)You may choose our shipping partner or your own partner.

› Maintenance

We are pleasant to share our theory and experience on equipment maintenance with users.

We are pleasant to interact with users to collect their tips and know-hows on equipment maintenance.

The module “Maintenance” here is intended to help users solve various problems they possibly encounter during equipment maintenance…

If you need other power electroplating rectifiers, we can custom design them according to customer requirements. Please contact us.

Are you looking for 700A 80V Aluminum Anodizing Rectifier? Liyuan Haina Group is one of the professional manufacturers and suppliers in this field. With over 27 years of focus on R&D, design, production, sales, and technical services for industrial rectifiers, we have already exported our products to the United States, Canada, India, Pakistan, Britain, Italy, Spain, South Africa, Russia, the UAE, Japan, South Korea, Malaysia, and other parts of the world. Equipped with a productive factory, we warmly welcome you to purchase our high-quality, Made-in-China products at competitive prices or try our customized service.

Hot Tags: 700A 80V Aluminum Anodizing Rectifier, Anodizing Rectifier, Anodizing Rectifier Manufacturers, industrial rectifiers

![]() File Download

File Download

Liyuan Haina Rectifier, the professional manufacturer in IGBT and SCR rectifier, committed to providing you with quality solutions and products.

Get more details? We’ll response as soon as possible (within 12 hours).

Liyuan Haina Rectifier, the professional manufacturer in IGBT and SCR rectifier, committed to providing you with quality solutions and products.

Get more details? We’ll response as soon as possible (within 12 hours).