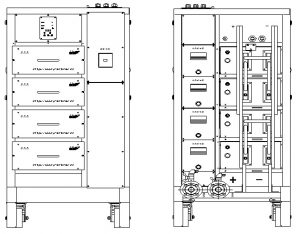

Input parameters: Three phase, AC380V±10% ,50HZ

Output parameters: DC 0~12V 0~12KA

Output mode: Common DC output

Cooling method: Water cooling

Power supply type: IGBT-based

Application Industry: Surface treatment industry, such as copper and chrome plating

12V 12KA Chrome Plating Rectifier, featuring an innovative configuration of 4 units of 3000A IGBT rectifier modules in parallel. This cutting-edge rectifier is equipped with an advanced Human-Machine Interface (HMI) control mode, allowing for flexible settings tailored to different stages and recipes of the chrome plating process. With the ability to check historical data records and streamline operations, our rectifier is designed to simplify and enhance your chrome plating workflow. 4 units of 3000A IGBT rectifier modules in parallel, HMI control mode for intuitive operation, customizable settings for various stages and recipes, historical data record tracking for analysis and optimization, user-friendly interface for easy operation and labor savings.

Enhanced Control: The HMI control mode of our Chrome Plating Rectifier enables precise adjustments at different stages of the plating process, ensuring optimal results and seamless workflow management.

Data Analysis: By accessing historical data records, users can analyze performance trends, identify areas for improvement, and optimize their chrome plating operations for maximum efficiency and quality.

User-Friendly Interface: The intuitive design of the HMI control mode makes operation simple and straightforward, reducing the need for extensive training and saving valuable labor hours.

Streamlined Operations: With flexible settings, historical data tracking, and user-friendly controls, our rectifier streamlines the chrome plating process, enhancing productivity and overall operational efficiency.

Experience the future of chrome plating technology with our 12V 12KA Chrome Plating Rectifier. Empower your operations with advanced control, data analysis, and user-friendly features that simplify and elevate your chrome plating workflow.

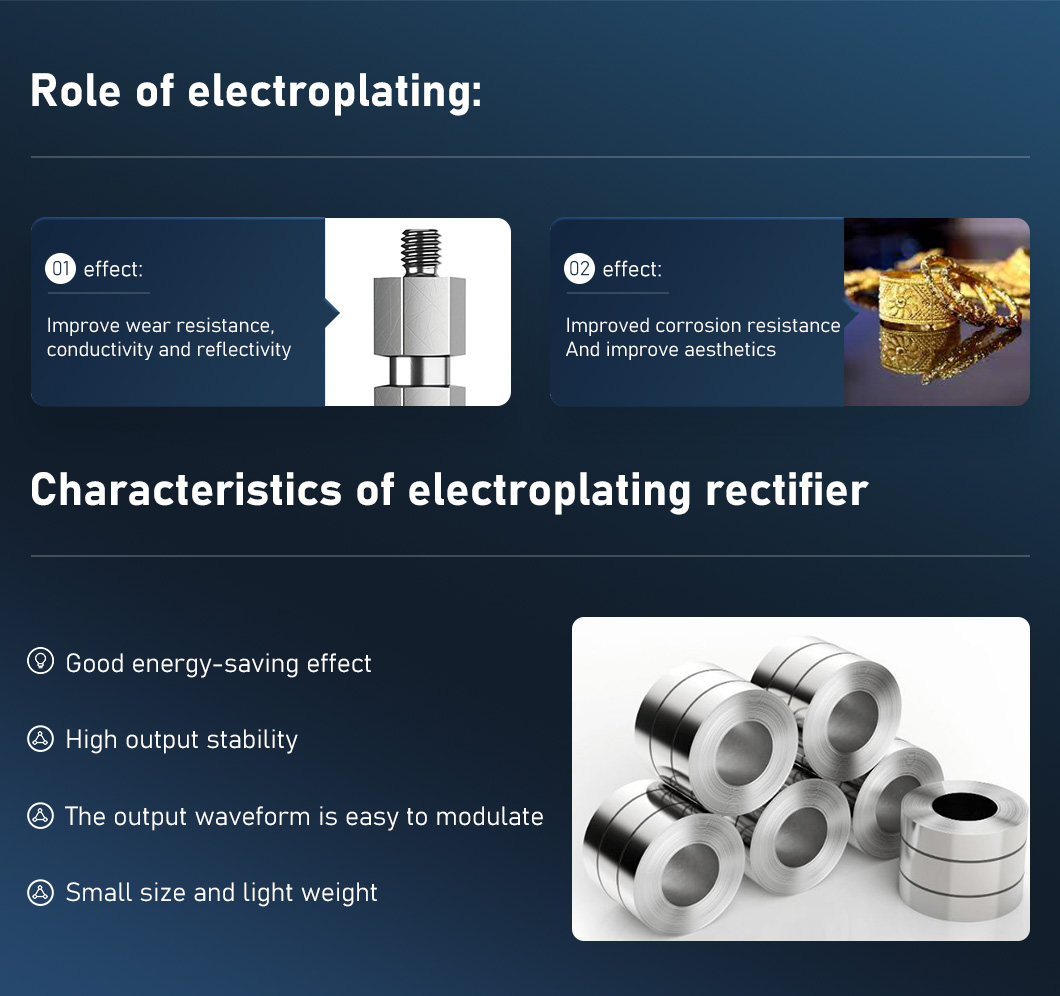

Electroplating is the process of applying a thin layer of other metals or alloys on the surface of certain metals by electrolysis. It is a process of applying a metal film to the surface of metals or other materials to prevent metal oxidation (such as rust), improve wear resistance, electrical conductivity, reflectivity, corrosion resistance (copper sulfate, etc.) and enhance aesthetics.

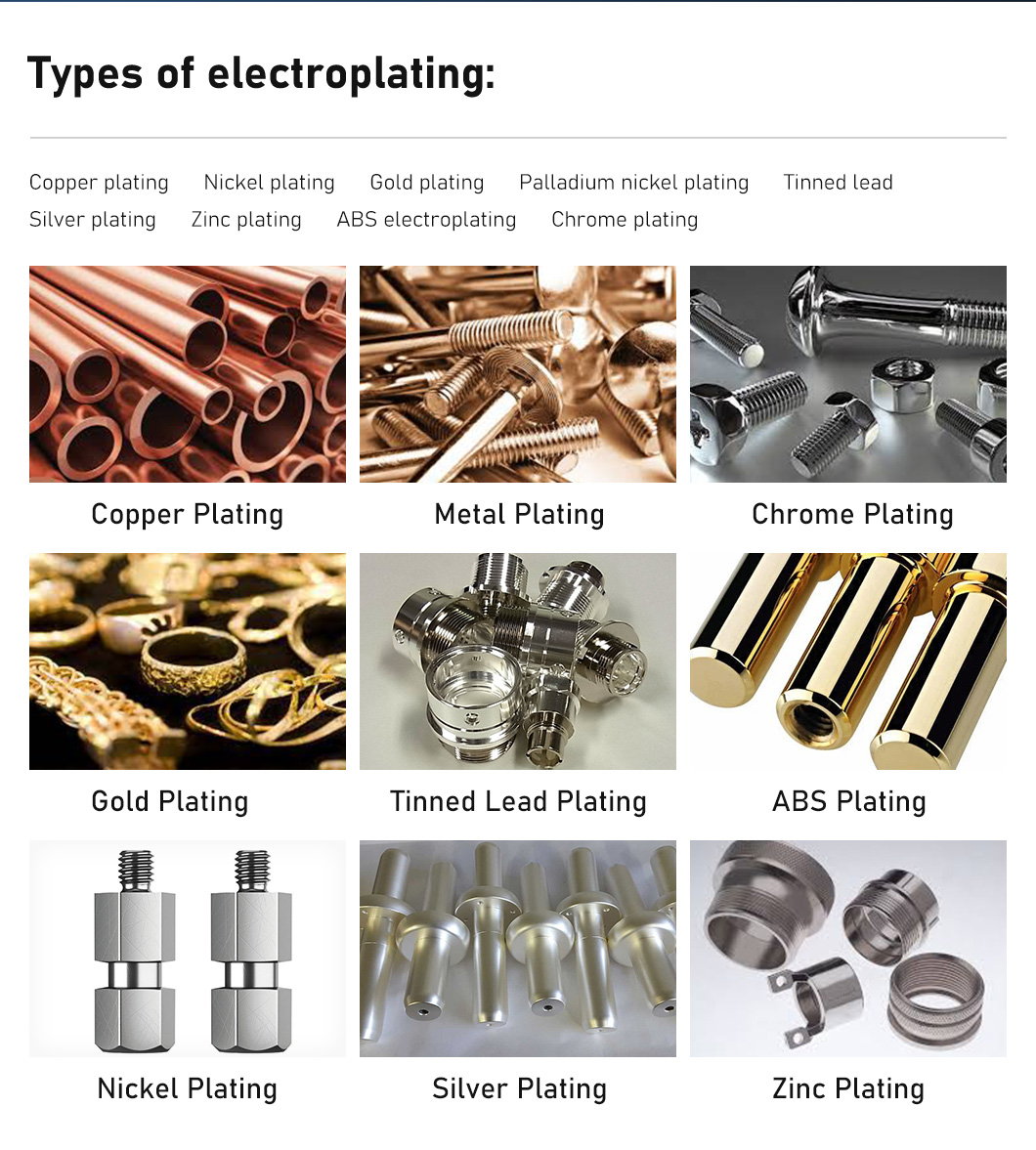

Types of plating

Elements of electroplating

Characteristic Types |

Parameter Items |

Technical Requirements |

| Power Types | Power types | High-frequency Power Supply |

| Model and specifications | TBSB-12KA/12V | |

| Cooling mode | Water-cooled | |

| Switch tube type | IGBT | |

| Input Characteristics | Rated Input Voltage | Three-phase, AC380V±10% ,50HZ |

| Rated Input Power | 76.6 KW | |

| Rated Input Current | AC 116A | |

| Input Power Factor | COSΦ≥0.95 | |

| Output Characteristics | Output Voltage | DC 0~12V |

| Output Current | DC 0~12KA | |

| Stabilized Current Precision | ≤1%(Rated Current) | |

| According to accuracy | 1A,0.01V | |

| Rated Output efficiency | ≥94% | |

| Environmental Conditions | Installation site | Indoor installations |

| Altitude | ≤2000 meters | |

| Ambient temperature | -20℃~40℃ | |

| Relative humidity | ≤90% | |

| Control Mode | Operating mode | PLC, ADDA, Ethernet, RS485 and RS232 |

| Weight | Net weight | About 90KG |

| External Dimension | Height*Width*Depth | H1200mm×W600mm×D700mm |

| Protection Characteristics | With over voltage, over current, overload, short circuit, overheating and other abnormal self-protection function | |

| Application | Model | Output Parameters |

| Plating | TBFB-500A/5V | 5Vdc/500A |

| TBFB-600A/10V | 10Vdc/600A | |

| TBFB-1000A/10V | 10Vdc/1000A | |

| TBFB-1500A/10V | 10Vdc/1500A | |

| TBFB-5000A/15V | 15Vdc/5000A | |

| HISB-200A12V | 12Vdc/200A | |

| HISB-300A12V | 12Vdc/300A | |

| HISB-500A12V | 12Vdc/500A | |

| HISB-1000A8V | 8Vdc/1000A | |

| HISB-1000A12V | 12Vdc/1000A | |

| HISB-1500A12V | 12Vdc/1500A | |

| HISB-2500A12V | 12Vdc/2500A | |

| HISB-3000A12V | 12Vdc/3000A | |

| HISB-4000A12V | 12Vdc/4000A | |

| HISB-5000A12V | 12Vdc/5000A | |

| HISB-7000A12V | 12Vdc/7000A | |

| TBSB-8000A/12V | 12Vdc/8000A | |

| TBSB-4000A/12V | 12Vdc/4000A | |

| TBSB-8000A/12V | 12Vdc/8000A | |

| TBSB-3000A/12V | 12Vdc/3000A | |

| TBSB-400A/4V | 4Vdc/400A | |

| TBSB-800A/12V | 12Vdc/800A | |

| TBFA-4000A/12V | ±12Vdc/4000A | |

| HMFB-10A5V | 5Vdc/10A | |

| TBFA-2000A/12V | ±12Vdc/2000A | |

| TBFBZ-300A/5V | 5Vdc/300A | |

| TBFBZ-800A/5V | 5Vdc/800A | |

| TBFBZ-600A/6V | 6Vdc/600A | |

| TBSB-12KA/12V | 12Vdc/12KA | |

| TBSB-6000A/12V | 12Vdc/6000A | |

| TDSB-10KA100V | 100Vdc/10KA |

Hot Tags:Hard Chrome Plating Rectifier,Surface treatment industry,Chrome Plating Rectifier 12V 12KA,hard chrome plating rectifier,plating rectifier manufacturers,dc rectifier electroplating,igbt plating rectifier,China,factory,sale,price

Liyuan Haina Rectifier, the professional manufacturer in IGBT and SCR rectifier, committed to providing you with quality solutions and products.

Get more details? We’ll response as soon as possible (within 12 hours).

Liyuan Haina Rectifier, the professional manufacturer in IGBT and SCR rectifier, committed to providing you with quality solutions and products.

Get more details? We’ll response as soon as possible (within 12 hours).