Input parameters: Three phase, AC380V±10% ,50HZ

Output parameters: DC 0~12V 0~2000A

Output mode: Common DC output

Cooling method: Air cooling

Power supply type: IGBT-based

Application Industry: Surface treatment industry, such as zinc plating

Introducing our high-performance 12V 2000A IGBT Type Zinc Plating Rectifier, engineered to deliver unparalleled efficiency and reliability for your plating operations. With an impressive efficiency rating of up to 94%, this rectifier sets a new standard for energy-saving performance. Its versatile design offers both air-cooled and water-cooled options, providing flexibility to suit varying requirements.

Unmatched Efficiency: With its advanced IGBT technology and exceptional 94% efficiency, our Zinc Plating Rectifier ensures minimal energy wastage, leading to significant cost savings and environmental benefits.

Versatile Cooling Options: The flexibility of air-cooled and water-cooled configurations allows for seamless integration into diverse operational environments, catering to specific cooling requirements with ease.

Reliable Performance: Built with durability and reliability in mind, this rectifier guarantees consistent, precise, and high-quality outcomes, making it a trusted asset for your zinc plating processes.

Experience the next level of efficiency and performance with our 12V 2000A IGBT Type Zinc Plating Rectifier. Invest in a solution that maximizes productivity while minimizing energy consumption — it’s the ultimate combination of innovation and sustainability.

Elevate your zinc plating operations with our advanced rectifier technology. Choose the efficiency, reliability, and flexibility that your operations demand. Order now and empower your business with the best in zinc plating rectification.

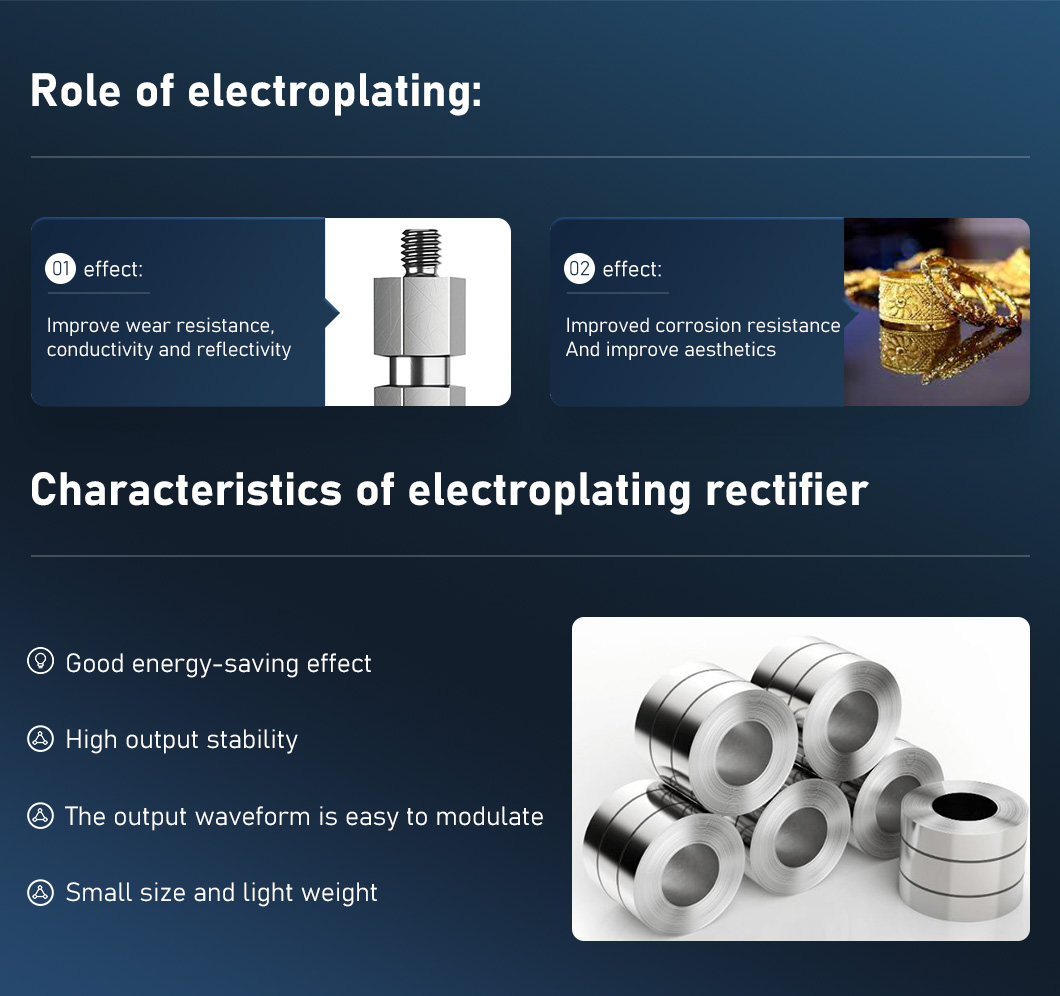

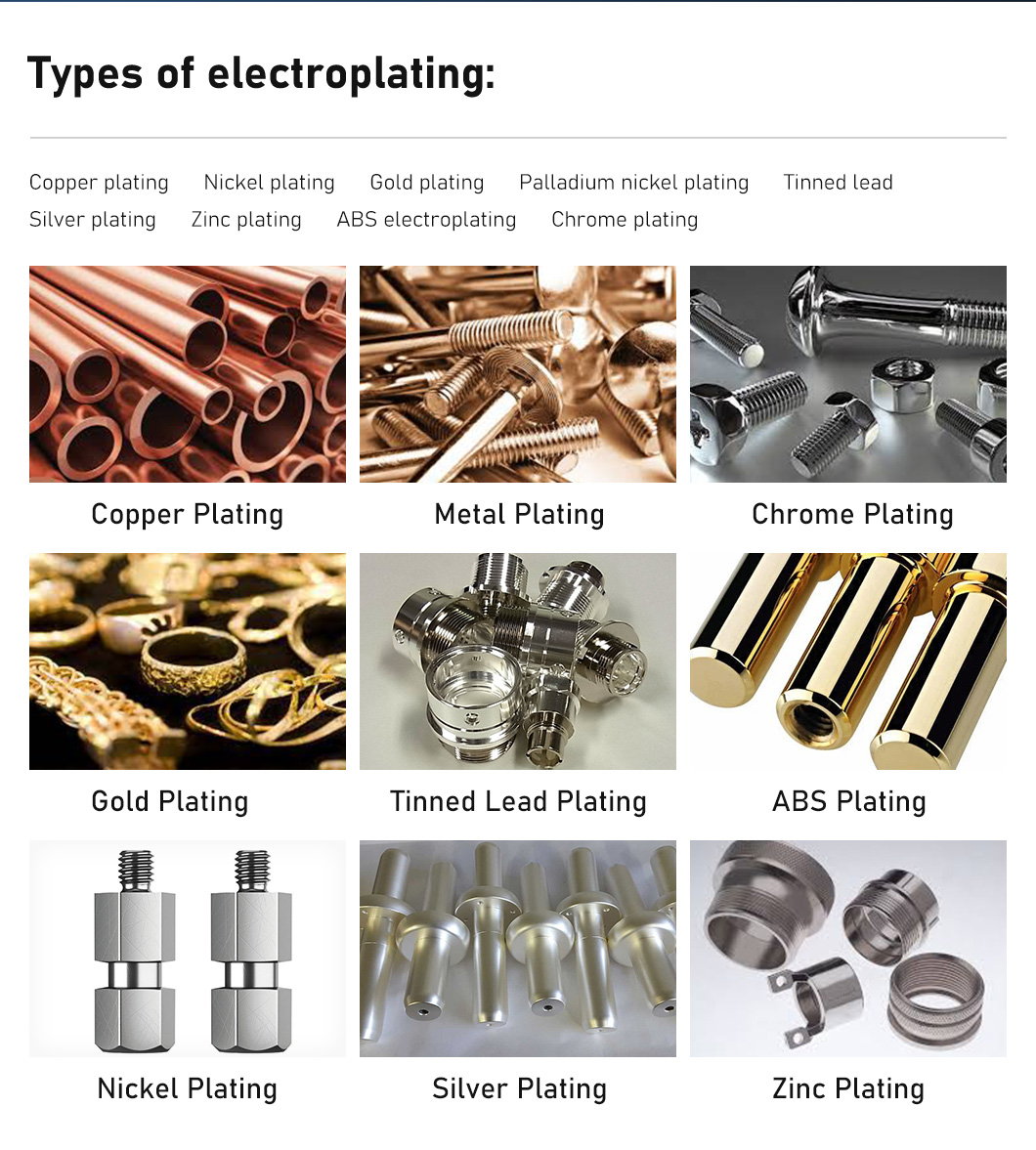

Electroplating is the process of applying a thin layer of other metals or alloys on the surface of certain metals by electrolysis. It is a process of applying a metal film to the surface of metals or other materials to prevent metal oxidation (such as rust), improve wear resistance, electrical conductivity, reflectivity, corrosion resistance (copper sulfate, etc.) and enhance aesthetics.

Types of plating

Elements of electroplating

Characteristic Types |

Parameter Items |

Technical Requirements |

| Power Types | Power types | High-frequency Power Supply |

| Model and specifications | TBFB-2000A/12V | |

| Cooling mode | Air-cooled | |

| Switch tube type | IGBT | |

| Input Characteristics | Rated Input Voltage | Three-phase, AC380V±10% ,50HZ |

| Rated Input Power | 50.4 KVA | |

| Rated Input Current | AC 72.7A | |

| Input Power Factor | COSΦ≥0.95 | |

| Output Characteristics | Output Voltage | DC 0~12V |

| Output Current | DC 0~2000A | |

| Stabilized Current Precision | ≤1%(Rated Current) | |

| According to accuracy | 1A,0.01V | |

| Rated Output efficiency | ≥94% | |

| Environmental Conditions | Installation site | Indoor installations |

| Altitude | ≤2000 meters | |

| Ambient temperature | -20℃~40℃ | |

| Relative humidity | ≤90% | |

| Control Mode | Operating mode | PLC, ADDA, Ethernet, RS485 and RS232 |

| Weight | Net weight | About 56KG |

| External Dimension | Height*Width*Depth | H185mm×W362mm×D966mm |

| Protection Characteristics | With over voltage, over current, overload, short circuit, overheating and other abnormal self-protection function | |

| Application | Model | Output Parameters |

| Plating | TBFB-500A/5V | 5Vdc/500A |

| TBFB-600A/10V | 10Vdc/600A | |

| TBFB-1000A/10V | 10Vdc/1000A | |

| TBFB-1500A/10V | 10Vdc/1500A | |

| TBFB-5000A/15V | 15Vdc/5000A | |

| HISB-200A12V | 12Vdc/200A | |

| HISB-300A12V | 12Vdc/300A | |

| HISB-500A12V | 12Vdc/500A | |

| HISB-1000A8V | 8Vdc/1000A | |

| HISB-1000A12V | 12Vdc/1000A | |

| HISB-1500A12V | 12Vdc/1500A | |

| HISB-2500A12V | 12Vdc/2500A | |

| HISB-3000A12V | 12Vdc/3000A | |

| HISB-4000A12V | 12Vdc/4000A | |

| HISB-5000A12V | 12Vdc/5000A | |

| HISB-7000A12V | 12Vdc/7000A | |

| TBSB-8000A/12V | 12Vdc/8000A | |

| TBSB-4000A/12V | 12Vdc/4000A | |

| TBSB-8000A/12V | 12Vdc/8000A | |

| TBSB-3000A/12V | 12Vdc/3000A | |

| TBSB-400A/4V | 4Vdc/400A | |

| TBSB-800A/12V | 12Vdc/800A | |

| TBFA-4000A/12V | ±12Vdc/4000A | |

| HMFB-10A5V | 5Vdc/10A | |

| TBFA-2000A/12V | ±12Vdc/2000A | |

| TBFBZ-300A/5V | 5Vdc/300A | |

| TBFBZ-800A/5V | 5Vdc/800A | |

| TBFBZ-600A/6V | 6Vdc/600A | |

| TBSB-12KA/12V | 12Vdc/12KA | |

| TBSB-6000A/12V | 12Vdc/6000A | |

| TDSB-10KA100V | 100Vdc/10KA |

Hot Tags:Zinc Plating Rectifier,2000A 12V IGBT Electroplating Rectifier for Zinc,dc rectifier electroplating,galvanizing rectifier,igbt plating rectifier,Surface treatment industry,zinc plating,electroplating rectifier manufacturer,igbt electroplating rectifier,China,manufacturers,factory,sale,price

Liyuan Haina Rectifier, the professional manufacturer in IGBT and SCR rectifier, committed to providing you with quality solutions and products.

Get more details? We’ll response as soon as possible (within 12 hours).

Liyuan Haina Rectifier, the professional manufacturer in IGBT and SCR rectifier, committed to providing you with quality solutions and products.

Get more details? We’ll response as soon as possible (within 12 hours).