Input parameters: Three phase, AC380V±10% ,50HZ

Output parameters: DC 0~22V 0~22KA

Output mode: Common DC output

Cooling method: Water cooling

Power supply type: IGBT-based

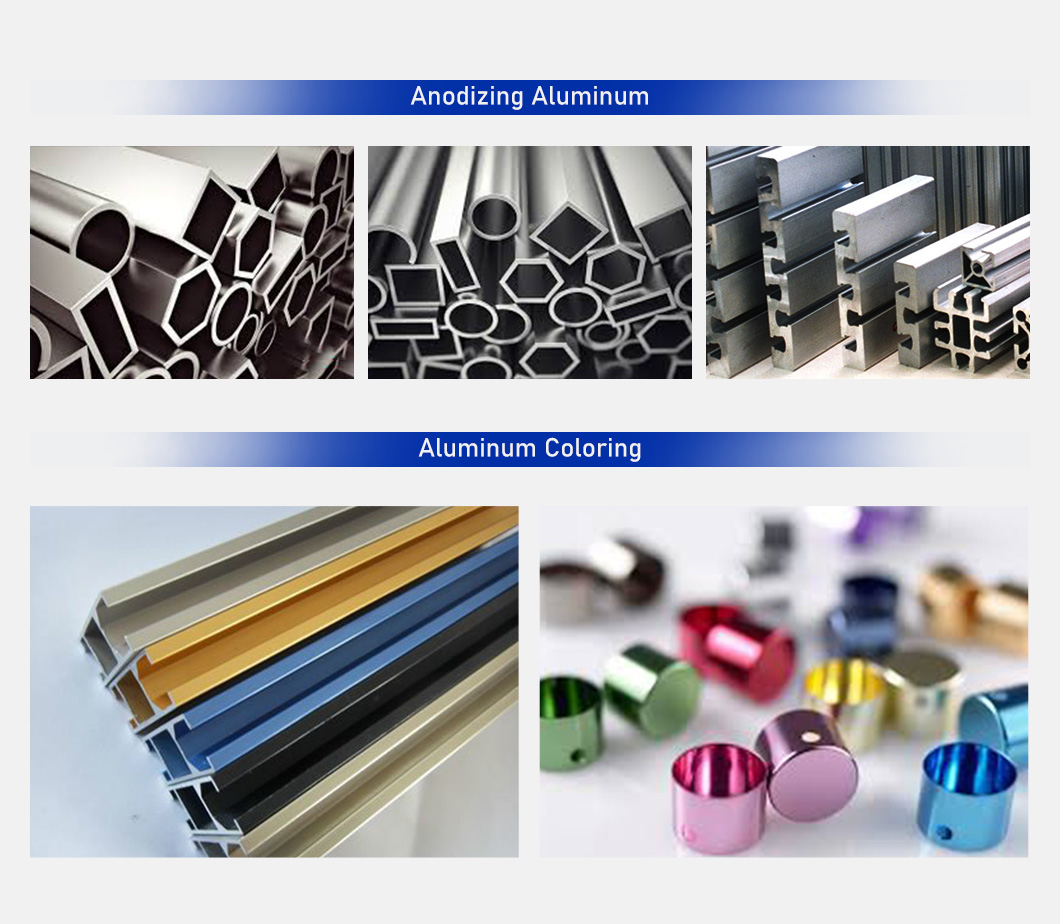

Application Industry: Oxidation of aluminium profile

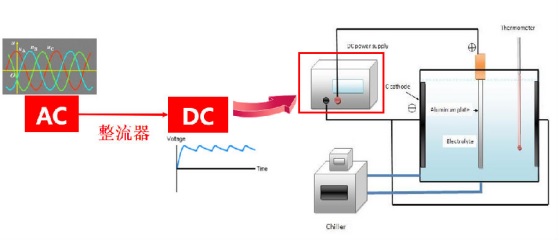

Aluminum oxidation (also known as anodizing) is an electrochemical process used for the surface treatment of aluminum and its alloys, with the primary purpose of enhancing the corrosion, abrasion, and aesthetic properties of aluminum. Prior to oxidation, the aluminum surface needs to be thoroughly cleaned to remove oil, dirt and oxides. Commonly used cleaning agents include alkaline and acidic cleaners. After cleaning, aluminum parts are often acid etched to further remove surface oxidation and irregularities. Commonly used acids include sulfuric acid and hydrofluoric acid. The cleaned and acid-etched aluminum parts are immersed in an electrolytic bath, where the electrolyte is usually a sulfuric acid solution. By the action of the electric current, a film of aluminum oxide is formed on the surface of the aluminum. The time and current density of anodizing affect the thickness and nature of the film. After anodizing, aluminum parts can be dyed to obtain different colors. Dyeing is usually done after the oxide film is formed. In order to improve the corrosion resistance of the oxide film, a sealing treatment is usually applied. Sealing can be done by hot water sealing or chemical sealing to fill the pores in the oxide film.

When oxidizing aluminum, it is necessary to ensure that the temperature and humidity of the operating environment are appropriate to ensure the consistency of the oxidation effect. Sulfuric acid concentration and temperature have an important influence on the formation of the oxide film and need to be strictly controlled. Due to the use of acidic and electrolytic solutions, operators should wear appropriate protective equipment such as gloves, goggles and protective clothing to prevent chemical damage to skin and eyes. The waste liquid generated from the oxidation process contains acids and must be disposed of properly in accordance with local environmental regulations. For dyeing and sealing treatment, appropriate materials and methods need to be selected to ensure the quality and performance of the final product. With the above procedures and precautions, aluminum oxidation treatment can be carried out effectively to enhance the performance and appearance of aluminum.

For the environment with corrosive gases, or the use of harsh environments, we usually use a fully sealed design, internal parts coated with three-proof paint and special sealing strips to ensure that the oxidized rectifier is not corroded and prolong the service life.

Anodic oxidation includes both aluminum anodizing and hard anodizing. Anodic oxidation (anodic oxidation), electrochemical oxidation of metals or alloys. The process of forming a layer of oxide film on aluminum products (anodes) under the action of an applied current in aluminum and its alloys under the corresponding electrolyte and specific process conditions. The so-called anodic oxidation of aluminum is an electrolytic oxidation process in which the surface of aluminum and aluminum alloys is usually transformed into a layer of oxide film, which has protective, decorative and some other functional properties.

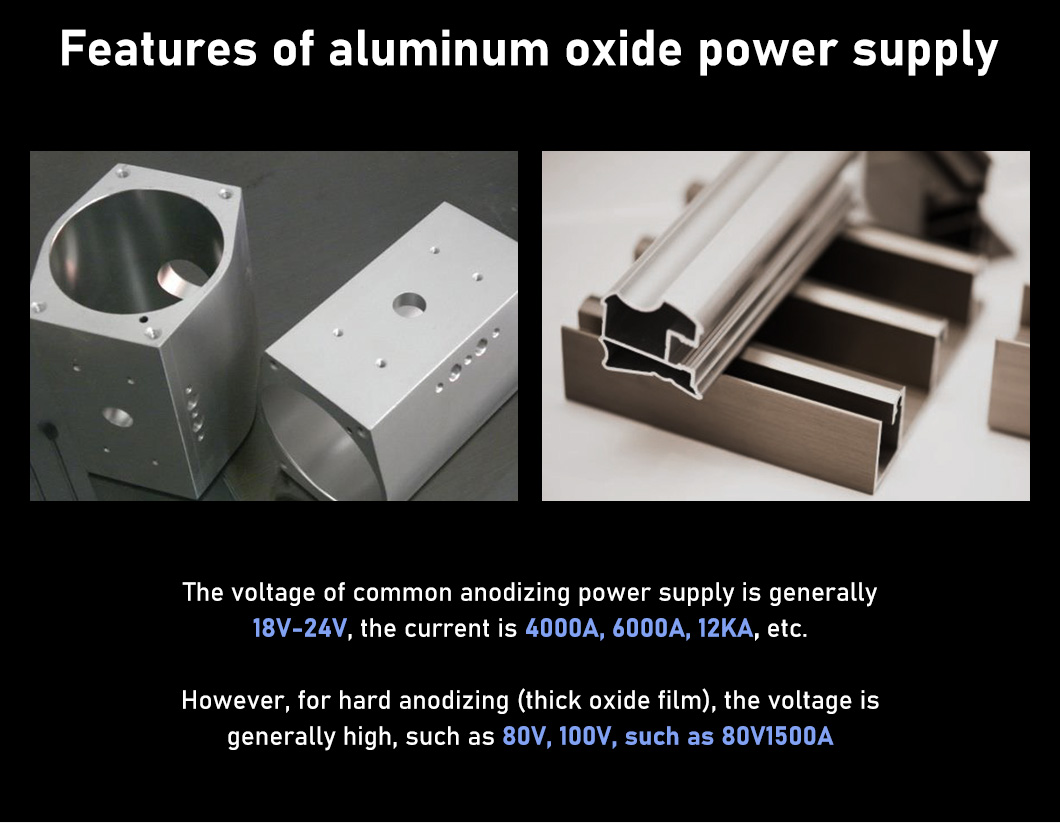

Ordinary decorative anodizing requires a DC power supply voltage of usually 20V-24V, while hard anodizing usually has a higher voltage depending on the process, sometimes reaching 80V, 100V, 120V, etc. The current is determined by the size of the workpiece to be anodized, ranging from a few hundred amps to tens of thousands of amps.

Aluminum oxidation coloring, using artificial methods to make aluminum and its alloy products surface to generate a layer of oxide film (Al2O3) and apply different colors, in order to improve the wear resistance of aluminum, prolong the service life and increase the color and beauty. The basic process of oxidation coloring is aluminum surface treatment, oxidation, coloring and subsequent hydration sealing, organic coating and other treatment processes. The coloring methods of oxide film are chemical coloring, electrolytic coloring and natural coloring, etc.

| Characteristic Types | Parameter Items | Technical Requirements |

| Power Types | Power types | High-frequency Power Supply |

| Model and specifications | TBSB-22KA/22V | |

| Cooling mode | Water-cooled | |

| Switch tube type | IGBT | |

| Input Characteristics | Rated Input Voltage | Three-phase, AC380V±10% ,50~60HZ |

| Rated Input Power | 562KW | |

| Rated Input Current | AC 853A | |

| Input Power Factor | COSΦ≥0.95 | |

| Output Characteristics | Output Voltage | DC 0~22V |

| Output Current | DC 0~22KA | |

| According to accuracy | 10A,0.01V | |

| Rated Output efficiency | ≥90% | |

| Environmental Conditions | Installation site | Indoor installations |

| Altitude | ≤1500 meters | |

| Ambient temperature | -20℃~45℃ | |

| Relative humidity | ≤90% | |

| Control Mode | Operating mode | PLC, ADDA, Ethernet, RS485 and RS232 |

| External Dimension | Height*Width*Depth | H2250mm×W1500mm×D1380mm |

| Protection Characteristics | With over voltage, over current, overload, short circuit, overheating and other abnormal self-protection function | |

| Application | Model | Output Parameters |

| Aluminum anodizing | TBSB-2500A25V | 25Vdc/2500A |

| TBSB-100A30V | 30Vdc/100A | |

| TBSB-1000A25V | 25Vdc/1000A | |

| TBSB-750A25V | 25Vdc/750A | |

| TBSB-700A40V | 40Vdc/700A | |

| TBSB-500A40V | 40Vdc/500A | |

| TBSB-300A50V | 50Vdc/300A | |

| TBSB-200A24V | 24Vdc/200A | |

| TBSB-100A40V | 40Vdc/100A | |

| TBSB-100A24V | 24Vdc/100A | |

| TBSB-50A20V | 20Vdc/50A | |

| TBSB-16KA22V | 22Vdc/16KA | |

| TBSB-14KA22V | 22Vdc/14KA | |

| TBSB-12KA22V | 22Vdc/12KA | |

| TBSB-16KA22V | 22Vdc/16KA | |

| TBSB-12KA22V | 22Vdc/12KA | |

| TBSB-1000A15V | 15Vdc/1000A | |

| TBSB-18KA25V | 25Vdc/18KA | |

| TBSB-12KA20V | 20Vdc/12KA | |

| TBSB-20KA150V | 150Vdc/20KA | |

| KGFB-2000A20V | 20Vdc/2000A | |

| KGSB-50KA1000V | 1000Vdc/50KA | |

| TBSB-22KA22V | 22Vdc/22KA | |

| KGFB-1500A/80V | 80Vdc/1500A | |

| TBSB-15KA/22V | 22Vdc/15KA | |

| KGSB-4KA250V | 250Vdc/4KA | |

| TBSB-24KA/22V | 22Vdc/24KA | |

| Colouring | DC/AC-500A/30V | DC/AC-500A/30Vdc |

| DC/AC-12KA25V | DC/AC-12KA25Vdc |

If you need other anodizing rectifier, we can custom design them according to customer requirements. Please contact us.

Seeking 22V 22KA aluminum anodizing rectifier manufacturer? Liyuan Haina Group, a professional manufacturer with 27+ years specializing in industrial rectifiers, supplies global clients including the United States, Canada, Britain, Italy, Spain, South Africa, Russia, the UAE, Japan, South Korea, Malaysia, etc. Our advanced factory delivers cost-effective Made-in-China solutions, with competitive prices and customizable options. Contact us for sales inquiries.

Hot Tags: 22V 22KA Aluminum Anodizing Rectifier Manufacturer, Anodizing rectifier, Aluminum oxidation, oxidizing aluminum, Manufacturer, price, sale

Liyuan Haina Rectifier, the professional manufacturer in IGBT and SCR rectifier, committed to providing you with quality solutions and products.

Get more details? We’ll response as soon as possible (within 12 hours).

Liyuan Haina Rectifier, the professional manufacturer in IGBT and SCR rectifier, committed to providing you with quality solutions and products.

Get more details? We’ll response as soon as possible (within 12 hours).