An Industrial Power Supply Rectifier, or simply known as a Rectifier in industrial power supply contexts, is a crucial device in various industrial applications. Here is a brief overview of its key aspects:

1.Definition of Industrial Power Supply Rectifier

An Industrial Power Supply Rectifier is an electronic device designed to convert alternating current (AC) into direct current (DC). It plays a vital role in industrial power systems by providing a stable and reliable DC power supply.

2.The Working Principle of Industrial Power Supply Rectifier

The working principle of an Industrial Power Supply Rectifier involves several key components:

Transformer: Transforms the input AC voltage to a desired level.

Rectifying Circuit: Converts the AC voltage into DC voltage using diodes, thyristors, or other semiconductor devices.

Filtering Circuit: Smooths out any remaining AC ripples in the DC output to provide a clean and stable DC power.

3.Types of Industrial Power Rectifier

Industrial power supply rectifiers are categorized based on various factors such as their control capabilities, circuit structures, and intended applications. Here are some of the main types:

Controlled Rectifiers

Three-Phase Semi-Controlled Rectifier: This type of rectifier has a relatively high voltage regulation range and accuracy. It works by first passing three-phase AC through a transformer to reduce the voltage, and then inputting it into the rectification circuit. The output voltage can be adjusted based on different control methods.

Three-Phase Fully Controlled Rectifier: This rectifier regulates the output voltage by controlling the indirectly sequenced current based on the principle of power modulation. It offers a wide range of output voltage adjustment and high precision, making it suitable for applications such as DC motors and power systems.

Uncontrolled Rectifiers

Single-Phase Half-Wave Rectifier: This is a simple type of rectifier that uses a single diode to convert the positive half-cycle of AC into DC, while the negative half-cycle is blocked. It has a simple structure and low cost but produces an unstable output current, making it unsuitable for industrial control.

Single-Phase Full-Wave Rectifier: Compared to the half-wave rectifier, the full-wave rectifier uses two diodes or a bridge rectifier circuit to convert both half-cycles of AC into DC, resulting in a more stable output current.

Three-Phase Bridge Rectifier: Also known as a rectifier bridge, this is one of the most commonly used rectifiers in industrial settings. It is suitable for applications where the input voltage is three-phase AC and the output is DC. The three-phase AC voltage is first reduced by a transformer and then input into the bridge rectifier, which uses four diodes to rectify the voltage and produce a stable and reliable output voltage.

Ordinary Rectifiers vs. Special Rectifiers

Ordinary Rectifiers: These are primarily used to convert AC into DC for use by electronic devices.

Special Rectifiers: These not only have rectification functions but also integrate filtering, voltage stabilization, and other functions to meet specific application requirements, such as those found in switching power supplies.

In summary, industrial power supply rectifiers come in various types, each with its own unique characteristics and suitable applications. When selecting a rectifier, it is important to consider factors such as the required output voltage and current, the type of AC input, and the specific needs of the industrial application.

4.Application of Industrial Power Supply Rectifier

Industrial Power Supply Rectifiers are widely used in:

Electronics Manufacturing: For powering various electronic devices and systems.

Electroplating: To provide the necessary DC power for processes like zinc-nickel plating.

Electrolysis: In industries involving the electrolysis of sodium hydroxide, salt, or water.

Electric Motors and Drives: For controlling the speed and direction of electric motors.

Power Distribution Systems: For maintaining power quality and providing backup power.

5.The Characteristics of Industrial Power Supply Rectifier

High Efficiency: Modern rectifiers can achieve high energy conversion efficiencies, often exceeding 88%.

Reliability and Durability: Designed to withstand harsh industrial environments and operate continuously for long periods.

Compact Design: Easier to install and maintain in industrial settings.

Protection Features: Incorporate various protection mechanisms to prevent damage from overvoltage, overcurrent, and other faults.

In conclusion, an Industrial Power Supply Rectifier is an indispensable device in many industrial applications. Its ability to convert AC power into stable DC power makes it a critical component in various systems and processes. With its high efficiency, reliability, and compact design, it continues to play a vital role in the industrial sector.

The development history of industrial power supply rectifiers is a testament to the advancements in electrical engineering, power electronics, and semiconductor technology. Here's a detailed overview of its evolution:

Early Development of Industrial Power Supply Rectifier

Mechanical Rectifiers: In the late 19th and early 20th centuries, with the advent of electrical engineering, power began to be widely used in industrial production. During this period, rectification technology mainly relied on mechanical rectifiers or simple electron tube rectifiers. However, these rectifiers suffered from low efficiency, large size, and complex maintenance.

Semiconductor Technology Emergence: In the 1940s, the emergence of semiconductor technology provided new possibilities for the development of rectifiers. Notably, the invention of the transistor in 1948 marked the beginning of practical applications of semiconductor technology.

Semiconductor Industrial Power Supply Rectifier development

Silicon Controlled Rectifier (SCR): In 1957, General Electric (GE) invented the Silicon Controlled Rectifier (SCR), later internationally named as Thyristor. The SCR was a semi-controlled device that greatly promoted the development of rectification technology. Due to its high power capacity, mature application technology, and low price, it quickly gained widespread use in the field of power electronics.

Other Semiconductor Rectifying Devices: Following the SCR, various new semiconductor rectifying devices emerged. For example, in the late 1970s, Gate Turn-Off Thyristors (GTOs) and Giant Transistors (GTRs) were developed, which addressed some of the shortcomings of the SCR in certain applications.

Development of Modern Industrial Power Supply Rectifier

MOS-Type Power Devices: In the late 1970s and early 1980s, Metal Oxide Semiconductor (MOS)-type power devices began to emerge. Among them, the Metal Oxide Semiconductor Field Effect Transistor (MOSFET) was an important voltage-controlled device. It had simple drive circuits and fast switching speeds, making it ideal for high-frequency applications.

Insulated Gate Bipolar Transistor (IGBT): In the early 1980s, researchers combined MOSFETs and GTRs (or Bipolar Junction Transistors, BJTs) to develop the Insulated Gate Bipolar Transistor (IGBT). The IGBT combined the fast switching speed of the MOSFET and the low on-state voltage drop of the GTR, quickly gaining widespread adoption in the field of power electronics. The advent of the IGBT marked a new stage in the development of rectification technology.

New Material Power Devices: In recent years, with the continuous development of new material technologies, wide bandgap semiconductor materials such as Gallium Nitride (GaN) and Silicon Carbide (SiC) have been applied in the manufacture of rectifiers. These new materials have high bandgap widths, high saturation electron drift velocities, and high breakdown strengths, making rectifiers based on these materials excel in high-temperature, high-frequency, and high-power applications.

Application and Development Trend of Industrial Power Supply Rectifier

Application Fields of Industrial Power Supply Rectifiers: Rectifiers are widely used in various industrial power supplies, power electronic equipment, communication devices, and other fields. Especially in emerging fields such as renewable energy, electric vehicles, and smart grids, the demand for rectifiers is constantly growing.

Future Trends in Industrial Power Supply Rectifiers: The future development trend of rectifiers will be towards high efficiency, high power density, miniaturization, and intelligence. With the continuous emergence of new materials and processes, the performance of rectifiers will continue to improve, and their application fields will continue to expand.

In conclusion, the development history of industrial power supply rectifiers is a continuous process of innovation and progress. From early mechanical rectifiers to modern semiconductor rectifiers, and now to high-performance rectifiers based on new materials, the development of rectification technology has not only driven advancements in electrical engineering and power electronics but also provided powerful impetus for industrial production and social development.

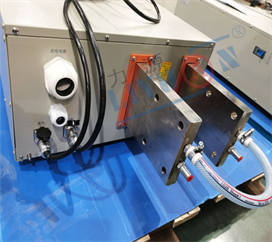

Liyuan Haina Rectifier Group(Consist of Zhengzhou Liyuan Haina Rectifier Co., Ltd. &Jiangxi Liyuan Haina Rectifier Co., Ltd.& Dongguan Liyuan Haina Rectifier Co., Ltd. & Shenzhen Liyuan Haina Energy Co., Ltd .) was founded in 1997, is one National High-tech enterprise, which specializes in development and manufacture of IGBT Rectifier, Silicon controlled rectifier, Synchronous rectified power supply, Pulse power supply,Pulse silicon rectifier, Pulse Variable-frequency power supply and Energy-saving Power supply, company constantly absorb top technology from Italy, Germany, Japan and America, especially in high-frequency power supply with high-power needs, energy-saving synchronous power supply with high-power and SCR rectifier equipment with high power, company has accumulated much rich experience, a strong team of personnel in the research and development, which has very mature technology, at the same time, we pay much attentions to various fields in the energy-saving, intelligent improvement and promotion.

Liyuan has 53000m² Production Workshop and 7 advanced production line, containing SMT, wave soldering machine, coated connection table and Metal digital machine etc. Our products can meet the special needs of various industries on rectifier.

Company's main products including: DC power supply, high -power high -frequency switching power supply, high -power energy -saving synchronous high -frequency switch power supply, high -power silicon rectifier, pulse power supply, inverter power supply, electric vehicle charging pile module power supply, electric energy quality product APF, appf SVG and high -power APFC, Peak Valley Energy Energy saving inverters, and microclippot inverters.

Our Products are widely used in various industry like: Electrolysis, PCB plating, Metallurgy, Anodizing, Coloring, Electrophoresis, Electrochemical, Testing, Electrolytic gas, Electrolytic copper foil, Electrolytic nuclear raw materials, Environmental protection electrolysis, Water treatment electrolysis, Rare Earth electrolysis, Heating power supply, Surface treatment industry and etc.

The products have take high market share in the electrolytic copper foil industry, and also we are the leading pioneer to apply synchronous rectified technology into rectifier design in the world.

The PCB board electroplating industry maintain a large number of customers, especially the high-speed Positive&Negative Pulse Rectifier has broken the monopoly of imported products.

The increasing R&D investment every year, and cooperation with China's well-known universities, we has established the research center of national electric power conversion and control engineering technology.

At present, company is cooperating with Hunan university in the study of hydrogen energy storage methods of peak and valley energy-saving programs and devices.

Liyuan adheres to innovation and the continuous improvement of power conversion efficiency and product quality, possessing 5 international leading, 22 domestic top-level, 8 core invention patents, 23 utility model patents, and 7 appearance design patents.

Especially the related core patents of high-power synchronous rectifier power supply, stay ahead of the whole industry in China.

The ISO 9001 quality management system has been fully implemented in Liyuan, including quality inspection of components in warehouse, production process inspection, and final product inspection.

We adopt advanced scientific quality management system and the most stringent testing methods in the whole process to ensure the stability and reliability of products.

Liyuan Haina Group sticks to the business philosophy of "professional, brand, innovation, service" and the principle of "quality-oriented, customer first", stick with the hydrogen production technical(ALK/AEM/PEM/SOEC) closely with conditions, including photovoltaic wind power hydrogen production, electrolysis hydrogen production in the transportation field, hydrogen production in smelting industry, etc., to optimize technology, maximize efficiency, lower power consumption, equipment investment costs, and maintenance costs.

Over the years, Liyuan Haina's products have been to thousands of users domestically and internationally, including Jiangxi Copper, Defu Electronics, Del Technology and other large-scale enterprises

Meanwhile, the products are also exported to the United States, Canada, Britain, Italy, England, Spain, South Africa, Russia, UAE, Japan, South Korea, Malaysia and other parts of the world.

About Industrial Power Supply Rectifier,Development History of Industrial Power Supply Rectifier,Innovation of Liyuan Haina in Power Supply Industry,China,USA,Germany,Sweden,manufacturers,factory,Power Supply,sale,price

Liyuan rectifier, taking the lead in IGBT rectifier and SCR rectifier in China.

Get more details? We’ll respond as soon as possible (within 24 hours).

Liyuan rectifier, taking the lead in IGBT rectifier and SCR rectifier in China.

Get more details? We’ll respond as soon as possible (within 24 hours).