Third-Gen Energy-Efficient Power Supply

Summary:

The text introduces the third-generation synchronous energy-saving IGBT rectifier, emphasizing its use in low-voltage industrial applications like PCB plating, chrome plating, copper plating, nickel plating, zinc plating, copper foil electrolysis. It highlights features such as full soft switching, high energy efficiency (up to 16% more than traditional types), easy maintenance, unique waterproof technology, and high stability. A comparison between the TB series and SCR (Schottky) type rectifiers is provided, showcasing TB's efficiency advantages despite its more complex production and smaller current capacity. Product parameters include input voltage, voltage and current regulation precision, rated efficiency, power factor, ripple wave coefficient, and operation environment. The text also delves into the technology behind the power supply, such as the use of high-performance MOS tubes, full-bridge soft switch technology, and a new structure with a high-frequency power transformer. Additional advantages include a small size, convenient maintenance, and a simplified water-cooled heat-dissipation structure. The third-generation power supply inherits the modularization of the second generation, enabling online hot standby and easy maintenance.

Synchronous energy-saving type IGBT Rectifier is our third generation self-developed product, mainly used in low-voltage applicant industry, such as surface treatment, water treatment, hydrogen electrolysis, metallurgy and other fields.

Advantages:

*Full soft switch, optional APFC, current harmonic <5% .

*Use of TB rectifier is more efficient, especially in low-voltage applications (e.g. PCB plating and copper foil electrolytic), its energy saving rate is 16% more than traditional type.

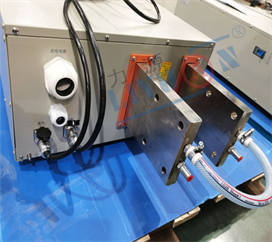

*The plug design facilitates maintenance and simplifies wiring.

*The unique waterproof technology is adopted in the whole water cooling mode, effectively prevent the hidden danger of condensate water, and adopts the non-joint cooling water pipe, which is safe and does not leak, and can be used in harsh environment.

*High stability and reliability and multi-loop control system.

Comparison between TB Series of Synchronous IGBT and SCR(Schottky) type:

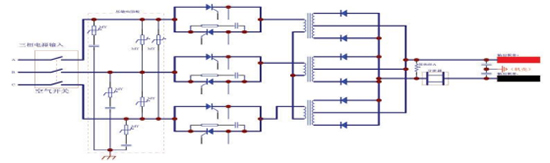

1.SCR Working Principle:

2.Synchronous Power Saving Type:

TB new generation IGBT rectifier advantages:

(1) TB rectifier is more efficient than schottky rectifier in output low voltage system due to lower voltage drop.

(2) TB rectifier is in the form of sheet-package, and the schottky rectifier is modular, TB series is more complicated than schottky rectifier during production.

(3) The current capacity of the TB rectifier is still smaller than schottky, so its quantity used is double than schottky at the same current.

With above comparison, TB rectifier advantages mainly on high efficiency and low power loss. But Schottky rectifier is simpler in structure and easier in maintenance.

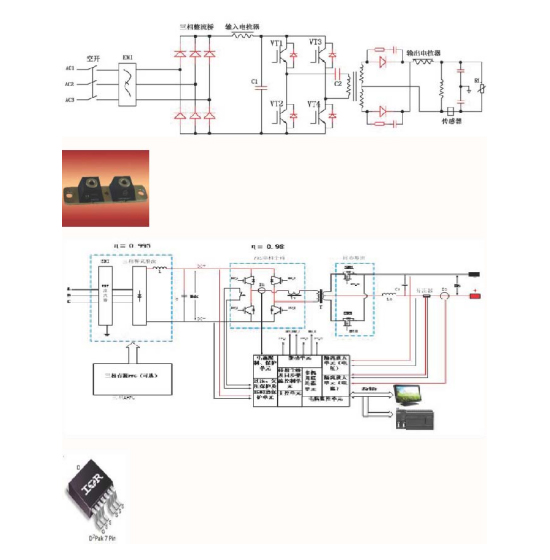

High performance, low on-resistance synchronous MOS tube is used as rectifier device to improve the efficiency of rectifier.

Due to the rapid development of the world's most advanced power semiconductor, high-performance devices are constantly emerging; especially the high-performance, low-on-resistance and high-current MOS tubes developed in recent years, as rectifier devices, have the characteristics of low on-voltage (0.1-0.2 V) and low reverse recovery loss, which greatly reduces the rectifier loss and greatly improves the overall efficiency of power supply. (Low voltage and high current situation.

Full-bridge soft switch technology used to minimize IGBT switching losses;

Using the most advanced adaptive resonant full-bridge PWM control IC, has the function of adaptive zero voltage delay control, supplemented by high efficiency resonant inductance, let the IGBT achieve ZVS almost at the whole working condition, reducing IGBT loss by 40%, at the same time improve the EMC characteristics and reduce the interference onto the power mains and the power supply itself.

Adopting the high power and low voltage drop IGBT as main switch component, largely lower the conduction lose:

which makes the working frequency of the third generation power supply twice of the second generation, and reduces the size of the magnetic material; at the same time, the low saturation voltage drop characteristic also reduces the IGBT power loss.

New structure and high frequency power transformer (Patent number: ZL201220244885.6; ZL201220248264.5);

High current path is parallel and short, and the area surrounded by high current is small, which improves the EMC characteristics of switching power supply and current circuit loss.

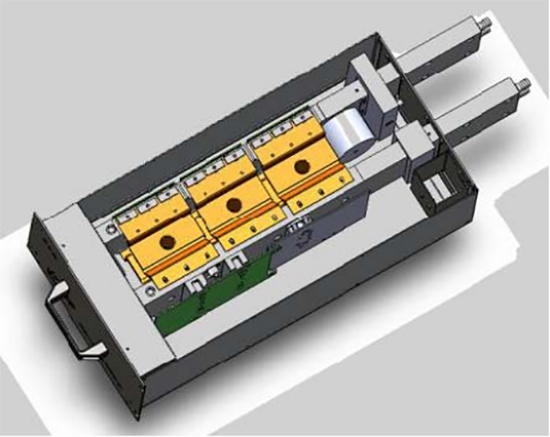

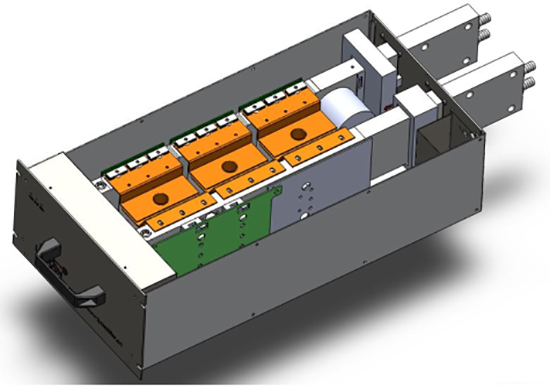

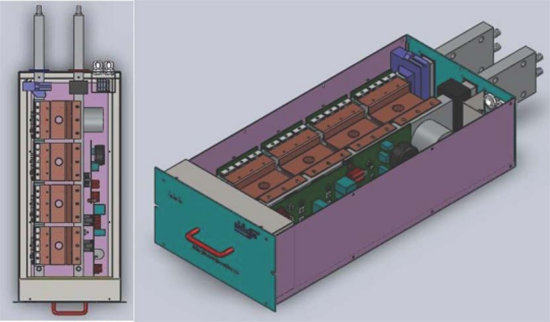

Structure advantages: small size and convenient maintenance(0-3000A)

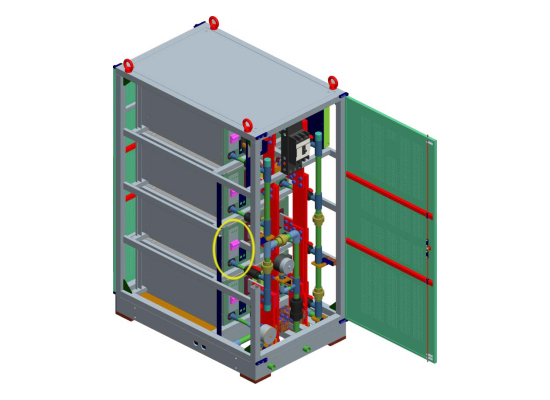

Water cooling pipe advantages: large diameter and long water pipe which can pass large water flow for cooling and no easy to scale, each branch pipe using same length connection, water pressure deviation is small, and no inside pipe joint totally avoid water leakage risk.

A highly simplified water-cooled heat-dissipation structure greatly reduces the failure rate due to the cooling cycle system. Various water pipes are optional (e.g. full copper pipe)

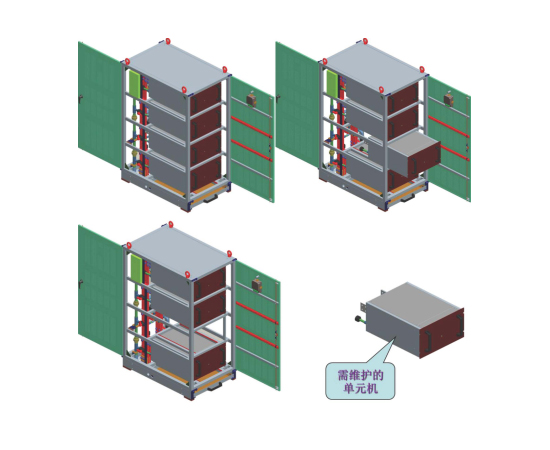

Low failure rate, easy to maintain, just remove the front panel and take the inside power unit outside for any questions.

Realized the On-line standby and maintenance: The third generation of new synchronous energy-saving power supply inherit the advantages of the second generation modularization, adopting the new drawer-type module to realize on-line hot standby and heat maintenance. Due to the higher efficiency, lower loss and higher frequency, and small size, light weight module advantages, which is easy to disassemble, carry and maintain.

Synchronous Energy-saving IGBT Rectifier,Third-Gen Energy-Efficient Power Supply,High Efficiency,Full-bridge Soft Switch Technology,Water Cooling,Modularization,surface treatment,water treatment,hydrogen electrolysis,PCB plating,chrome plating,copper plating,nickel plating,zinc plating,copper foil electrolysis,manufacturers,factory,Power Supply

Liyuan rectifier, taking the lead in IGBT rectifier and SCR rectifier in China.

Get more details? We’ll respond as soon as possible (within 24 hours).

Liyuan rectifier, taking the lead in IGBT rectifier and SCR rectifier in China.

Get more details? We’ll respond as soon as possible (within 24 hours).